Origins of Taslon Fabrics

Taslon fabric has its roots in nylon, developed in the 1930s, but with key advancements that make it more suitable for outdoor applications. The fabric was created to offer greater durability, flexibility, and resistance to wear than traditional nylon. Originally, it was used in military applications for its strength and resistance to environmental stressors. Over time, its popularity spread to the outdoor industry, where it quickly became the fabric of choice for items like jackets, tents, and backpacks.

The name “Taslon” is often used to describe fabrics that are made from high-performance nylon fibers treated to enhance water resistance and durability. Modern Taslon fabrics are produced with advanced techniques that further improve their functionality, making them ideal for active use in challenging environments.

What is Taslon Fabric?

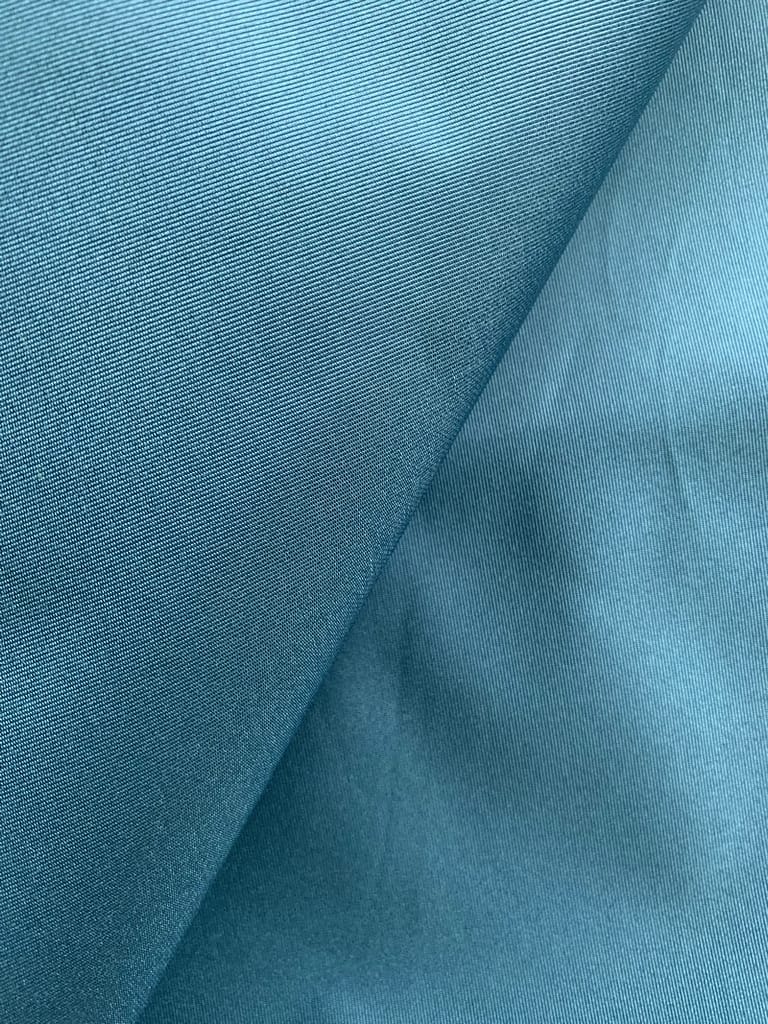

Taslon fabric is a type of nylon textile known for its unique combination of strength and lightweight properties. It is typically made from nylon 6 or 6,6, and is treated to enhance its durability, water resistance, and comfort. Unlike standard nylon fabrics, which can sometimes feel stiff or abrasive, Taslon is softer and more flexible, making it suitable for a wide range of outdoor applications.

One of the defining features of Taslon is its smooth surface, which allows for easy movement and comfort, especially in outdoor clothing and gear. The fabric is tightly woven, which helps it resist abrasions while still remaining breathable and lightweight. Compared to other synthetic fabrics, such as polyester, Taslon tends to offer better performance in terms of water resistance and tear strength, making it a preferred choice for activewear and outdoor enthusiasts.

Characteristics of Taslon Fabrics

Taslon fabrics are prized for their unique combination of durability, comfort, and performance in outdoor environments. Here are the key characteristics:

- Durability: Taslon is highly resistant to tearing and abrasion, making it ideal for outdoor gear that faces constant wear and tear, such as backpacks, jackets, and tents.

- Water Resistance: With water-repellent finishes, Taslon fabrics are designed to handle wet conditions, ensuring users stay dry even in rain or snow.

- Lightweight: Despite its strength, Taslon remains lightweight, offering freedom of movement without the bulk, perfect for activewear and outdoor apparel.

- Breathability: The fabric allows moisture to escape, helping to regulate temperature and keep the wearer dry during intense physical activities.

- UV Protection: Many Taslon fabrics include UV inhibitors, offering protection against harmful sun exposure, making it ideal for extended outdoor use.

Types of Taslon Fabrics

Taslon fabrics come in various types, each designed to meet specific needs in outdoor gear and apparel. Here are the most common variations:

Plain Weave Taslon: The standard version, known for its durability and smooth texture, making it ideal for jackets and outerwear.

Ripstop Taslon: Features a grid pattern that adds extra strength and resistance to tears, commonly used for backpacks, tents, and other gear subjected to heavy use.

Coated Taslon: This type is treated with additional coatings, such as polyurethane or PVC, to enhance water resistance and durability, often used for rain gear and outer shells.

Stretch Taslon: Blended with spandex or elastane, this version provides added flexibility, making it suitable for activewear that requires more mobility.

Each type of Taslon offers unique advantages, allowing manufacturers to choose the best material for different outdoor applications.

Production Process of Taslon Fabrics

The production of Taslon fabric is a multi-step process that involves specialized techniques to enhance its durability, water resistance, and flexibility. Here’s an overview of the key steps:

| Step | Description |

|---|---|

| Fiber Production | Taslon fabric is typically made from nylon fibers, such as nylon 6 or 6,6, known for their strength. These fibers are spun into yarns, which serve as the foundation of the fabric. |

| Weaving | The nylon yarns are woven into the fabric using a tight plain weave or other variations. This step ensures that the fabric is strong, durable, and resistant to abrasion. |

| Treatments | The fabric undergoes treatments to enhance its performance. This includes water-repellent finishes (like DWR) and UV inhibitors to improve water resistance and provide protection from the sun. |

| Finishing | The fabric is then softened and treated to reduce stiffness. This step also improves its texture, flexibility, and overall comfort, making it suitable for outdoor apparel. |

The result of this process is a high-performance fabric that combines durability, water resistance, and flexibility—qualities that make Taslon ideal for outdoor gear and activewear.

Uses of Taslon Fabrics

Taslon fabrics are versatile and widely used in a variety of outdoor gear and apparel. Here are some of the most common applications:

- Outdoor Clothing: Taslon is often used in jackets, pants, and coats due to its durability, water resistance, and lightweight properties. It provides comfort and protection in various weather conditions.

- Backpacks and Luggage: Its tear-resistant nature makes Taslon ideal for backpacks, duffel bags, and other travel gear, which are exposed to rough handling.

- Tents and Outdoor Shelters: The fabric’s strength and water resistance make it a popular choice for tents and tarps, where durability and protection from the elements are crucial.

- Sports Gear: Taslon is also used in items like sportswear, protective gear, and outdoor accessories, offering a balance of flexibility and strength for active use.

Taslon’s combination of strength, flexibility, and weather resistance makes it an essential material for a wide range of outdoor products.

Benefits of Taslon Fabrics for Outdoor Gear

Taslon fabrics provide several key benefits that make them ideal for outdoor gear:

- Durability: Resistant to tearing and abrasion, perfect for backpacks, jackets, and tents.

- Water Resistance: Treated to repel water, keeping you dry in wet conditions.

- Lightweight: Offers comfort and flexibility for active movements.

- Breathability: Allows moisture to escape, keeping you cool and dry during physical activity.

- Versatility: Ideal for a wide range of outdoor applications, from clothing to camping gear.

Taslon’s durability, water resistance, and comfort make it the preferred choice for outdoor enthusiasts.

Care of Taslon Fabrics

Taslon fabrics are designed for durability, but proper care is essential to maintain their performance over time. Here are some key tips for keeping Taslon gear in top condition:

- Washing: Machine wash Taslon items in cold water with a mild detergent. Avoid using bleach, which can damage the fabric’s water-repellent coating. For best results, turn garments inside out to reduce abrasion.

- Drying: Air-dry Taslon fabrics by hanging them up or laying them flat. Avoid tumble drying, as high heat can weaken the fabric and strip it of its water-resistant treatment.

- Reproofing: Over time, the water-repellent finish may wear off. Reapply a water-repellent treatment (such as DWR spray) to restore the fabric’s resistance to water.

- Storage: Store Taslon gear in a cool, dry place away from direct sunlight to preserve its color and integrity. Avoid storing it in damp environments, which could encourage mildew growth.

By following these simple steps, you can extend the life of your Taslon gear and maintain its performance.

Future Trends in Taslon Fabrics

Taslon fabrics are evolving to meet the demands of modern outdoor enthusiasts. Key trends to watch include:

- Eco-Friendly Innovations: There is a growing focus on sustainability, with manufacturers increasingly turning to recycled nylon and eco-friendly finishes. This shift reduces the environmental impact of Taslon fabrics while maintaining their performance.

- Enhanced Performance: Ongoing advancements in fabric treatments and coatings will further improve Taslon’s durability, water resistance, and breathability, making it even more suitable for extreme weather conditions and high-performance outdoor gear.

- Smart Fabrics: The integration of wearable technology is on the horizon. Smart Taslon fabrics could incorporate sensors to monitor body temperature or moisture levels, adapting to environmental conditions to enhance comfort during outdoor activities.

- Customization: Future Taslon fabrics may offer more options for customization, allowing consumers to select specific attributes such as weight, texture, or water resistance based on their individual outdoor needs.

These trends will keep Taslon fabrics at the cutting edge of outdoor apparel and gear, offering more sustainable, functional, and adaptable solutions for adventurers.

Conclusion

Taslon fabric has established itself as a go-to material for outdoor gear and apparel due to its unique combination of durability, lightweight nature, water resistance, and comfort. From its origins in military and outdoor applications to its widespread use in jackets, backpacks, tents, and activewear, Taslon continues to deliver reliable performance in harsh environments.

As the fabric evolves with innovations in sustainability, performance, and smart technology, its versatility and functionality are expected to grow. Whether you’re hiking, camping, or traveling, Taslon fabrics remain a trusted choice for those who demand high-performance materials that stand the test of time.