Introduction

For any clothing brand—whether you’re launching a new line or scaling an existing one—understanding the true cost of shirt manufacturing is critical. Pricing isn’t just about covering expenses; it’s about maintaining healthy margins, positioning your brand correctly in the market, and ensuring long-term sustainability.

Shirt production costs can vary widely depending on fabric choices, design complexity, production region, and order quantity. Without a clear grasp of these variables, brands often struggle with unexpected expenses, misaligned pricing, or inconsistent product quality.

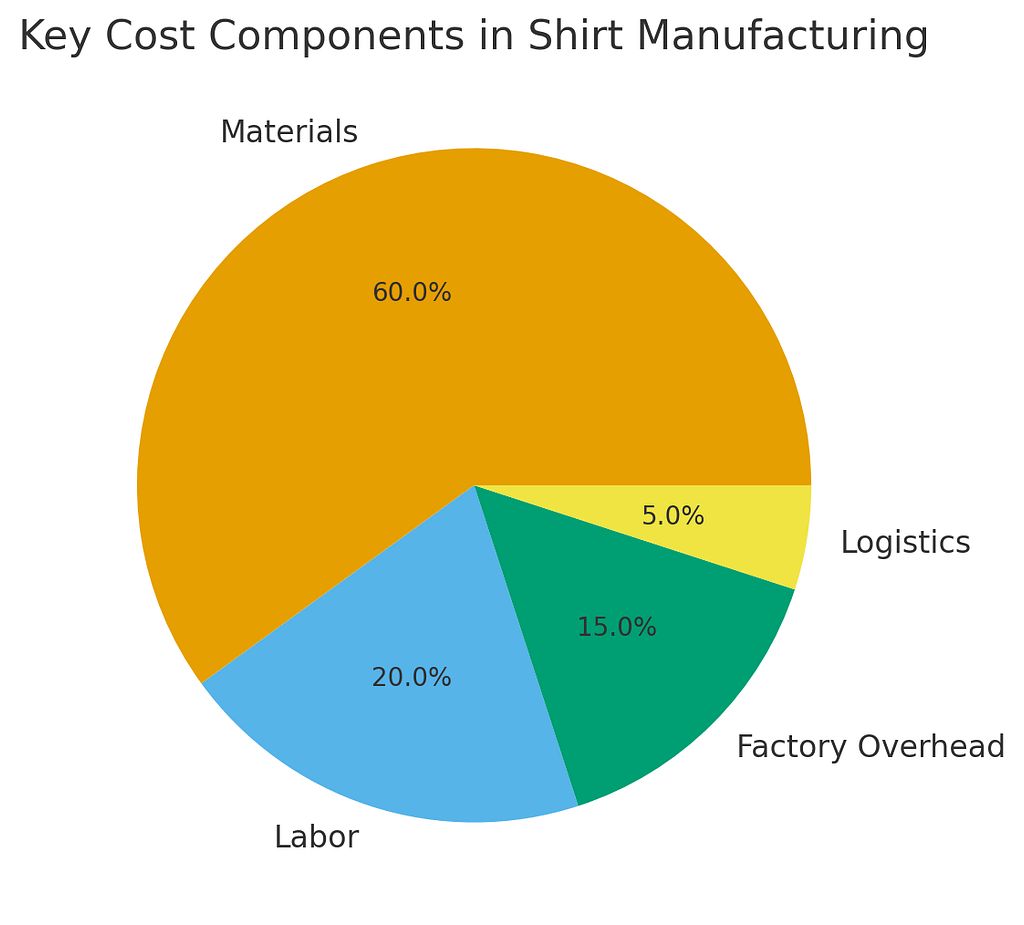

Key Cost Components in Shirt Manufacturing

Understanding how a shirt’s cost is built is essential for brands looking to price products correctly, maintain healthy margins, and scale production sustainably. While every shirt style has its own requirements, most production costs fall into four major categories: materials, labor, factory overhead, and logistics.

Materials (Fabric + Trims)

Materials typically make up 50–70% of the total production cost. The largest portion comes from the fabric itself—its fiber content, weight, finishing, and quality level all influence the final price. In addition to fabric, trims such as buttons, labels, threads, and packaging contribute to the total material cost. For more premium shirts, custom trims, branded packaging, or specialized finishing will push this cost higher.

Labor

Labor includes cutting, sewing, pressing, and finishing. The complexity of the shirt design directly impacts labor cost: a basic T-shirt requires fewer operations, while a woven button-down with plackets, collars, cuffs, and topstitching requires far more skilled labor and time. Labor rates also vary significantly by region—countries with more advanced compliance systems and higher wages generally produce at a higher cost.

Factory Overhead & Production Fees

Factories include overhead such as utilities, machine maintenance, management, compliance, and operational costs within their pricing. This portion also includes production line setup, which is why minimum order quantities (MOQs) matter; larger orders spread setup costs across more units, lowering the per-unit cost. Small batches typically result in higher pricing because overhead cannot be diluted.

Logistics

Freight, customs duties, and domestic handling are essential but often overlooked components of the total cost. Shipping mode (air vs. sea), import tariffs, and final destination all influence the landed cost of each shirt. Brands that plan ahead with production schedules can reduce logistics costs significantly by avoiding urgent air shipments.

Labor, Overhead & MOQs

Labor and factory overhead together shape a significant portion of shirt production costs. While materials dominate the budget, labor efficiency and order quantity strongly influence the final unit price.

Labor Costs

Labor includes cutting, sewing, pressing, and final finishing.

- Basic T-shirts require fewer operations and less time.

- Woven shirts with collars, plackets, and cuffs require more skilled work and higher labor cost.

The cost also varies by region—South Asia is generally more affordable, Southeast Asia balances skill and cost, while China and developed countries sit at the higher end due to wages and compliance standards.

Factory Overhead

Overhead covers factory operations such as utilities, machine maintenance, supervision, compliance, and workspace. These costs are spread across the production volume, meaning larger orders dilute overhead and significantly reduce the cost per unit.

Additional Costs Brands Often Miss

Beyond the core components of materials, labor, and overhead, there are several hidden or frequently overlooked costs that can significantly impact a shirt’s final price. Understanding these early helps brands avoid surprise expenses and manage budgets more accurately.

Sampling and Prototyping

Before bulk production begins, brands typically go through multiple rounds of sampling:

- Fit samples

- Pre-production samples

- Color and trim approvals

- Size set samples

Each sample requires fabric, trims, sewing time, and factory attention—often at a higher cost than bulk production. While necessary, these steps add to the overall investment and should be included in cost planning.

Quality Control and Testing

To ensure consistency and compliance, some brands require additional testing such as:

- Fabric shrinkage tests

- Colorfastness tests

- Chemical compliance tests (e.g., REACH, OEKO-TEX)

- Third-party inspections

Freight and Shipping

Logistics is a major cost component, especially for international production:

- Sea freight is cost-effective but takes longer.

- Air freight is fast but significantly more expensive.

- Freight forwarder fees, port charges, and handling fees add to the total cost.

Duties, Taxes, and Import Fees

Every country has its own tariff rates on apparel imports. These duties depend on:

- Country of origin

- Fabric composition

- HS code classification

Example: Cost Breakdown of a Basic Shirt

To help brands better understand how each cost component comes together, here is a simplified example of a cost breakdown for a basic, short-sleeve cotton T-shirt. Actual prices vary by region, fabric type, and order quantity, but this example illustrates the general cost structure.

Example: Basic Cotton T-Shirt (Based on 1,000 pcs Order)

1. Materials

- Fabric (cotton jersey, 180–200gsm): $2.00–$2.50

- Thread: $0.05

- Labels (brand, care, size): $0.10–$0.15

- Polybag + hangtag: $0.10–$0.20

Subtotal (Materials): $2.25–$2.90

2. Labor

- Cutting + sewing + finishing: $0.70–$1.20

(Labor varies based on region and factory efficiency.)

Subtotal (Labor): $0.70–$1.20

3. Factory Overhead & Profit

- Overhead allocation: $0.30–$0.50

- Factory margin: $0.20–$0.40

Subtotal (Overhead + Margin): $0.50–$0.90

4. Additional Costs

- Sampling (averaged per unit): $0.10–$0.15

- QC and inspection: $0.05–$0.10

- Freight (sea freight, averaged per unit): $0.10–$0.20

Subtotal (Additional): $0.25–$0.45

**Estimated Total Cost Per Shirt:

👉 $3.70–$5.45 per piece**

This means a brand targeting a typical retail markup (3–5× landed cost) would reasonably price the shirt at $18–$30 retail, depending on positioning.

How This Cost Changes

- Premium fabrics (Pima, Tencel, organic cotton) can double material cost.

- Complex construction (e.g., long sleeves, heavier hems) increases labor.

- Smaller orders (below 300 pcs) raise overhead significantly.

- Air shipping instead of sea can add $0.50–$2.00 per piece

How to Reduce Costs Without Hurting Quality

Controlling production costs doesn’t mean compromising on the product. Smart brands optimize their design, sourcing, and manufacturing processes to keep prices competitive while maintaining strong quality. Here are practical strategies that work well across the apparel industry.

Choose Materials Strategically

Fabric is the biggest cost driver, so even small adjustments make a noticeable difference.

- Opt for widely available fabrics instead of custom-developed textiles when budgets are tight.

- Use fabric blends (e.g., cotton-poly) to balance cost, durability, and softness.

- Consider slightly lower GSM weights that still maintain quality but reduce consumption.

- Avoid excessive finishes or specialty treatments unless they add real value for your target market.

Optimize Trims and Design Details

Unnecessary design details quickly increase labor and trim costs.

- Simplify seam lines, pockets, or paneling if they don’t enhance functionality.

- Use standard buttons, zippers, and labels for lower MOQs and lower costs.

- Standardize trim colors and sizes across multiple styles to get better bulk pricing.

- Streamline packaging to avoid costly custom boxes or specialty materials.

Build Long-Term Manufacturer Partnerships

Manufacturers offer better pricing, more flexibility, and improved production priority to brands that invest in long-term relationships.

- Consistent orders allow factories to allocate resources more efficiently.

- Good relationships lead to lower sampling fees, faster turnaround, and better support.

- Reliability benefits both sides and reduces overall risk.

Conclusion

Understanding the full cost structure behind shirt manufacturing is essential for brands that want to price accurately, protect margins, and plan production more strategically. Every element—materials, labor, overhead, logistics, and even sampling—plays a role in determining true cost, and brands that master these details are far better equipped to make informed sourcing decisions.

Clear visibility into each cost component helps brands optimize materials, streamline design details, and plan production schedules that reduce unnecessary expenses. At the same time, acknowledging additional costs such as testing and freight prevents unexpected surprises later in the process.

Ultimately, successful apparel production relies on transparency, communication, and strong operational alignment. Brands that collaborate closely with experienced manufacturing partners tend to achieve more stable quality, more reliable pricing, and smoother workflows.

As a B2B cross-border clothing manufacturer, GOPHERWOOD supports brands with transparent costing, efficient production planning, and high-quality garment manufacturing across categories. By combining strong technical expertise with global production capabilities, we help brands bring their collections to market with confidence, consistency, and long-term scalability.