History of Nylon Fabrics

Nylon, a synthetic fiber, was first introduced to the world in 1935 by the DuPont company, under the leadership of Wallace Carothers. Initially developed as a silk substitute, nylon’s introduction marked a major milestone in the evolution of synthetic materials. Its first commercial application was in women’s stockings, which rapidly gained popularity due to nylon’s sheer appearance and durability compared to silk.

During World War II, nylon became indispensable in the production of parachutes, ropes, and other military equipment due to its strength and resistance to wear. This period helped expand its recognition and solidified its reputation as a durable, versatile fabric.

Over the years, nylon evolved into a cornerstone material for various industries. Its impact extended beyond fashion into the automotive, aerospace, and home goods sectors. This fiber has remained relevant due to its unique properties, innovation potential, and ability to be adapted for specialized uses such as high-performance textiles and industrial materials.

What Is Nylon Fabric?

Nylon fabric is a type of synthetic fiber made from polymers, specifically polyamides. Developed in the 1930s, it was the first fully synthetic fiber to be mass-produced, marking a breakthrough in textile innovation. Unlike natural fibers such as cotton or wool, nylon is entirely man-made, created through chemical processes that result in a fabric with unique properties.

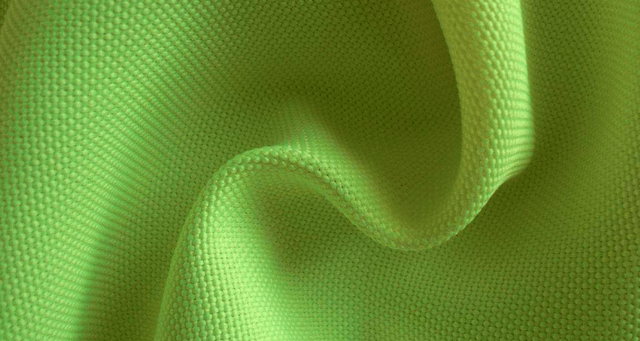

Nylon is known for its remarkable strength, flexibility, and lightweight nature. The fiber is highly durable, resisting wear and tear far better than most natural materials. This makes nylon ideal for items that require longevity, such as sportswear, outdoor gear, and industrial textiles.

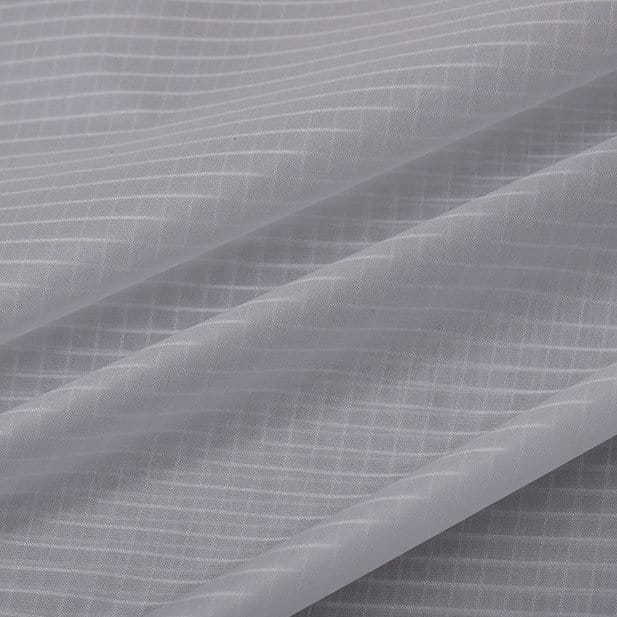

The fabric is also water-resistant and quick-drying, properties that make it a favorite for applications in raincoats, swimwear, and camping equipment. In addition, nylon’s elasticity allows it to stretch and return to its original form without losing shape, which is why it’s commonly used in hosiery and activewear.

Moreover, nylon fabric is easy to dye, allowing manufacturers to create vibrant colors that hold well over time. Its versatility in appearance and performance is why nylon remains a staple in both fashion and industrial uses today.

The Properties of Nylon Fabrics

- Strength and Durability – Resistant to abrasion and wear.

- Elasticity – Stretches and returns to its original shape.

- Water-Resistant – Repels moisture and dries quickly.

- Lightweight – Comfortable without sacrificing performance.

- Easy to Dye – Holds vibrant colors and is easy to maintain.

- Chemical and UV Resistance – Withstands harsh environments.

The Production Process of Nylon

Here’s a simplified table of the nylon production process:

| Step | Description |

|---|---|

| Polymerization | Monomers are chemically combined to form nylon polymer chains. |

| Extrusion & Spinning | Molten nylon is extruded through a spinneret to create long fibers. |

| Drawing | Fibers are stretched to increase strength and elasticity. |

| Texturizing | Fibers are twisted or curled to add texture and bulk. |

| Dyeing & Finishing | Nylon is dyed and may receive additional treatments (e.g., water-repellency). |

Types of Nylon Fabrics

Nylon fabrics come in several types, each with specific characteristics and uses. Here are the main types:

Nylon 6

This is one of the most commonly used nylon types, known for its flexibility, strength, and resistance to abrasion. Nylon 6 is widely used in textiles, carpets, and industrial applications due to its durability and performance.

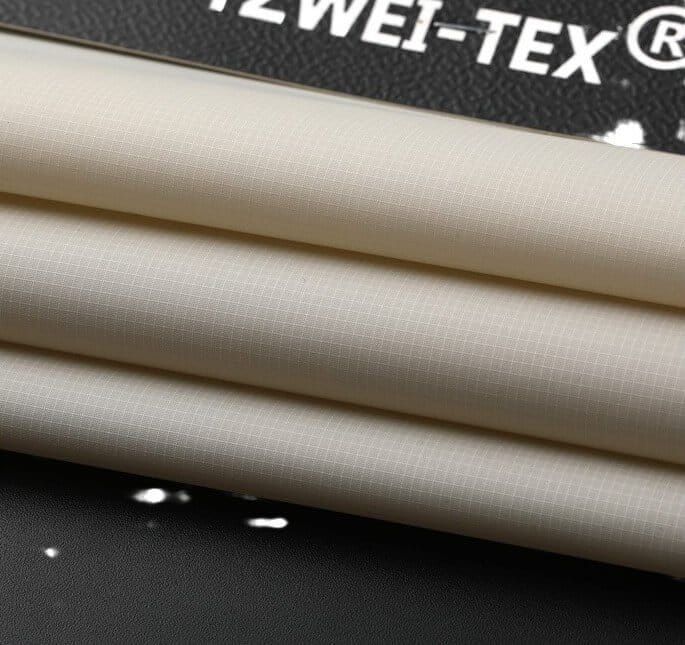

Nylon 66

Nylon 66 has a higher melting point and is more heat-resistant than Nylon 6. It is also stronger and stiffer, making it ideal for use in applications that require more toughness, such as in automotive parts, outdoor gear, and heavy-duty fabrics.

Nylon 11 and Nylon 12

These are more specialized nylons used for specific applications like in the automotive and medical industries. Nylon 11 and 12 have lower density, better flexibility, and higher resistance to chemicals and weather, making them suitable for tubing, connectors, and other specialized products.

Specialty Nylons

Other variants of nylon, such as high-temperature nylons, are used for specialized industrial applications that require enhanced heat resistance or specific mechanical properties.

Applications of Nylon Fabrics

- Fashion and Apparel – Used in activewear, swimwear, hosiery, and outerwear for its flexibility, durability, and lightweight properties.

- Industrial Uses – Ideal for ropes, parachutes, airbags, and tire cords due to its strength and resistance to abrasion.

- Home Textiles – Common in carpets, upholstery, and curtains for its stain resistance and ease of cleaning.

- Outdoor and Sporting Goods – Found in tents, backpacks, and sports equipment for its weather resistance and durability.

- Medical and Technical Fields – Used in medical devices and tubing because of its flexibility and chemical resistance.

Environmental Impact of Nylon Fabrics

Of course, there are some disadvantages of nylon fabrics that should not be ignored, such as:

- Non-Biodegradable – Nylon takes many years to decompose, contributing to long-term environmental waste.

- High Energy Production – The production of nylon requires significant amounts of energy, leading to a higher carbon footprint compared to natural fibers.

- Use of Non-Renewable Resources – Nylon is made from petrochemicals, which are derived from non-renewable fossil fuels, impacting resource sustainability.

- Microplastic Pollution – Washing nylon fabrics can release microplastics into water systems, which are harmful to marine life and ecosystems.

- Recycling Challenges – Although some recycling methods exist, recycling nylon is complex and not widely practiced, limiting its eco-friendliness.

Future Trends in Nylon Fabrics

- Sustainable Alternatives – Efforts are being made to develop bio-based nylons that use renewable resources, reducing the reliance on petrochemicals.

- Improved Recycling – Advancements in recycling technologies aim to make nylon recycling more efficient, reducing waste and promoting circular production models.

- Eco-Friendly Coatings and Treatments – Manufacturers are exploring environmentally friendly coatings that maintain nylon’s durability while minimizing its environmental footprint.

- High-Performance Nylon – Research is focusing on developing more advanced nylon materials that are stronger, lighter, and more heat-resistant, expanding its industrial and technical applications.

- Blended Fabrics – Combining nylon with other sustainable fibers like organic cotton or recycled polyester is a growing trend to create more eco-conscious, high-performance fabrics.

Conclusion

Nylon fabrics have proven to be a revolutionary material in various industries due to their strength, flexibility, and versatility. From fashion and sportswear to industrial and medical applications, nylon continues to play a crucial role. However, it also presents challenges, particularly in terms of its environmental impact, with concerns over its non-biodegradable nature and production-related pollution.

Looking ahead, innovation in sustainable nylon alternatives, recycling technologies, and eco-friendly treatments will be key to addressing these environmental issues. Despite its drawbacks, nylon remains an essential fabric in modern manufacturing, and with ongoing advancements, its role is likely to evolve in more sustainable and responsible ways.