Introduction

The T-shirt has evolved from a humble undergarment into one of the most iconic and versatile pieces in modern fashion. Its universal appeal lies in its simplicity, comfort, and endless potential for customization. Whether worn casually, as a branding tool, or a form of self-expression, the T-shirt adapts seamlessly across cultures, trends, and industries.

This article explores what it takes to craft the perfect T-shirt—diving into its design foundations, material selection, printing methods, and quality standards. From concept to creation, each stage contributes to a product that feels just right and looks effortlessly stylish.

Design Foundations

At the heart of every great T-shirt lies thoughtful design. The silhouette and fit set the stage for how the garment drapes on the body and how it makes the wearer feel. Classic cuts such as the crew neck, V-neck, and scoop neck each convey a different style language—crew necks offer timeless simplicity, V-necks add subtle elongation, and scoop necks create a relaxed, fashion-forward look. Beyond neckline, choices between slim, regular, and oversized fits determine whether the T-shirt feels tailored or street-ready.

Key pattern pieces work in harmony to bring these silhouettes to life. A typical T-shirt pattern consists of the front and back body panels, two sleeve panels, and a neckband or facing. Precise grading between sizes ensures consistent proportions, while strategic placement of shoulder seams and sleeve caps affects mobility and shoulder width. Additionally, graphic placement—whether centered chest prints, pocket-sized logos, or all-over patterns—must align with the body’s natural lines to achieve visual balance and wearable comfort.

Material & Fabric Choices

When it comes to crafting the perfect T-shirt, the fabric you choose is just as important as the design.

Fiber Selection

- 100% Cotton

- Combed and Ring-Spun: Combed cotton is softer; ring-spun has finer yarns and less pilling.

- Organic Cotton: Grown without harsh chemicals, appealing to eco-conscious consumers.

Blended Fabrics

- Cotton/Polyester (Typically 50/50 or 60/40): Improves wrinkle resistance, durability, and cost efficiency.

- Tri-Blends (Cotton/Polyester/Rayon): Offers a vintage drape, subtle sheen, and enhanced softness.

Specialty Synthetics

- Tencel (Lyocell) & Modal: Naturally sourced fibers with a silky hand, excellent drape, and moisture management.

- Performance Blends: Incorporate polyester or nylon with moisture-wicking finishes for athletic wear.

Knit Structure

Single Jersey

- The most common knit—lightweight, breathable, and slightly prone to curling at the edges.

Interlock Knit

- Double-knit construction yielding a thicker, more stable fabric; resists curling and offers cleaner hems.

Slub Jersey

- Features intentional yarn irregularities (“slubs”) that create a textured, vintage look.

Weight & Handfeel

- Lightweight (120–140 g/m²)

- Ideal for summer wear; extremely breathable but less opaque.

- Midweight (140–180 g/m²)

- Balances drape and opacity; most versatile for everyday tees.

- Heavyweight (180 g/m²+)

- Holds structure well; popular for streetwear and durable work-style tees.

Printing & Finishing Techniques

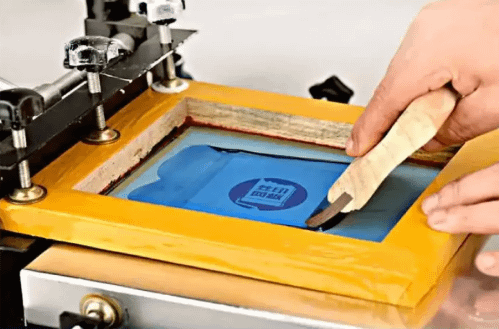

Screen Printing

- Process: Uses stencils (“screens”) to apply layers of ink; ideal for bold, vibrant colors and large batches.

- Pros: Cost-effective at scale, excellent opacity on dark fabrics, highly durable prints.

- Cons: Setup time and cost are higher for small runs; limited to simpler color palettes unless using multiple screens.

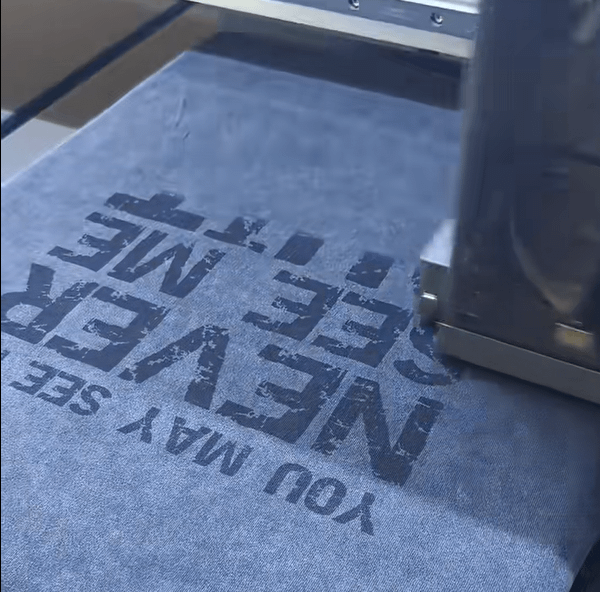

Direct-to-Garment (DTG) Printing

- Process: Inkjet technology sprays water-based inks directly onto the fabric; optimal for detailed, full-color designs.

- Pros: No screen setup, perfect for small batches or one-off designs, photographic-quality prints.

- Cons: Slower production speed, less vibrant on very dark shirts without a white underbase, ink cost per print higher.

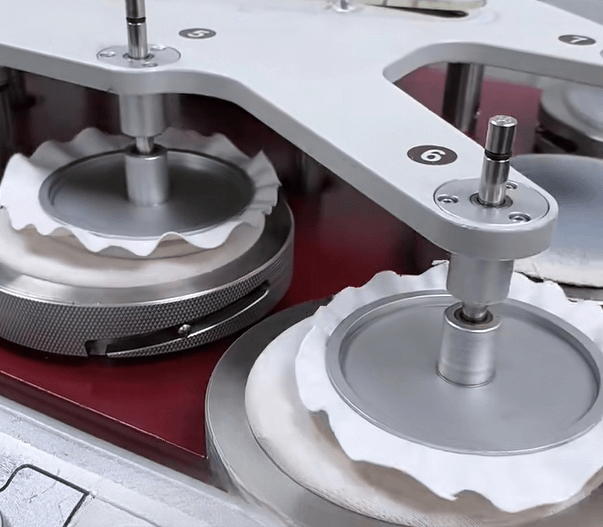

Heat Transfer and Vinyl

- Process: Designs are printed or cut on transfer paper/vinyl, then heat-pressed onto the fabric.

- Pros: Quick setup, versatile for custom names/numbers, works well on demand.

- Cons: Transfers can feel stiff over time; edges may peel if not pressed correctly.

Sublimation Printing

- Process: Dye inks turn to gas under heat and bond with polyester fibers; best for light-colored, polyester-rich fabrics.

- Pros: Produces vibrant, all-over prints that won’t crack or fade; fabric remains soft.

- Cons: Limited to polyester or high-poly blends; not suitable for 100% cotton.

Embellishments & Specialty Accents

- Embroidery: Adds textured, high-end logos and motifs; ideal for minimalistic branding.

- Appliqué: Sewn fabric patches create dimensional designs; offers a handcrafted look.

- Foil & Puff Prints: Provide metallic sheen or raised “puff” effects for standout graphics.

Garment Finishes

- Enzyme and Bio-Washes: Gently soften fabric and impart a vintage feel without heavy abrasion.

- Garment Dyeing: Pieces are dyed after assembly, yielding subtle color variations and a lived-in appearance.

- Coatings & Treatments: UV-resistant, water-repellent, or anti-odor finishes add functional performance.

Quality Control & Cost Considerations

Stitch Integrity & Seam Strength

- Stitch Density: Typically 12–14 stitches per inch (SPI) for body seams; higher SPI for stress points like shoulder and side seams.

- Tensile Testing: Seams are subjected to pull tests to measure the force required before failure—critical for durability.

Dimensional Stability & Shrinkage

- Pre- and Post-Wash Measurements: Swatch samples are laundered under industry-standard conditions (e.g., 60°C wash, tumble dry) to record shrinkage percentages.

- Acceptable Tolerances: Generally maintained within ±3% for length and width to ensure consistent fit.

Colorfastness & Print Durability

- Wash-Fastness: Printed samples endure multiple wash cycles; ratings (1–5 scale) assess fading or bleeding.

- Rub Test: Rubbing printed areas under dry and wet conditions checks for ink transfer and cracking.

Fabric Handfeel & Appearance

- Pilling Resistance: Martindale or Random Tumble Pilling tests gauge propensity for surface fuzz.

- Surface Uniformity: Visual inspections catch irregular knits, slubs, or dye streaks that could impact aesthetic quality.

Cost Drivers & Budget Management

- Material Costs: Premium fibers (e.g., organic cotton, Tencel) command higher yarn prices. Bulk purchasing can lower unit costs.

- Production Scale: Screen printing and cutting automation become more cost-effective over larger runs; DTG and heat transfer excel in small-batch scenarios.

- Labor & Location: Manufacturing in regions with skilled labor versus low-cost hubs requires balancing quality, lead time, and compliance costs.

Balancing Quality with Affordability

- Minimum Order Quantities (MOQs): Negotiating lower MOQs can reduce inventory risk but may raise per-unit cost.

- Design Optimization: Simplifying color separations in prints or reducing embellishments helps trim setup and material expenses.

- Supplier Audits & Partnerships: Long-term agreements with vetted suppliers often yield volume discounts and priority production slots.

Conclusion

Crafting the perfect T-shirt is a meticulous process that blends creativity, technical precision, and strategic choices. From selecting the ideal silhouette and fabric to applying the right print techniques and enforcing strict quality standards, every stage matters. A great T-shirt isn’t just about comfort—it’s about fit, feel, durability, and how well it expresses a brand’s identity.

At GOPHERWOOD, we specialize in B2B clothing manufacturing . From material sourcing to final stitching and finishing, our expert team is committed to helping global brands build premium apparel lines with confidence. Partner with us to bring your vision to life—crafted with care, delivered with precision.