Introduction

In today’s performance-driven and wellness-focused market, sports bras have evolved from basic activewear staples to highly engineered garments that blend style, support, and functionality. As consumer expectations grow, brands and designers are seeking ways to differentiate their collections through tailored fits, material innovation, and strategic design features.

For clothing manufacturers, understanding the distinctions between different sports bra styles is essential. Whether you’re creating a capsule line for a boutique brand or scaling up production for a major label, having in-depth knowledge of sports bra types can guide better design decisions, streamline sampling, and ensure that the final product meets both functional and aesthetic goals.

Core Sports Bra Constructions

Understanding the fundamental constructions behind sports bras is crucial for translating a designer’s vision into a manufacturable product. Each construction method carries implications for pattern complexity, material usage, cost, and ultimately consumer performance.

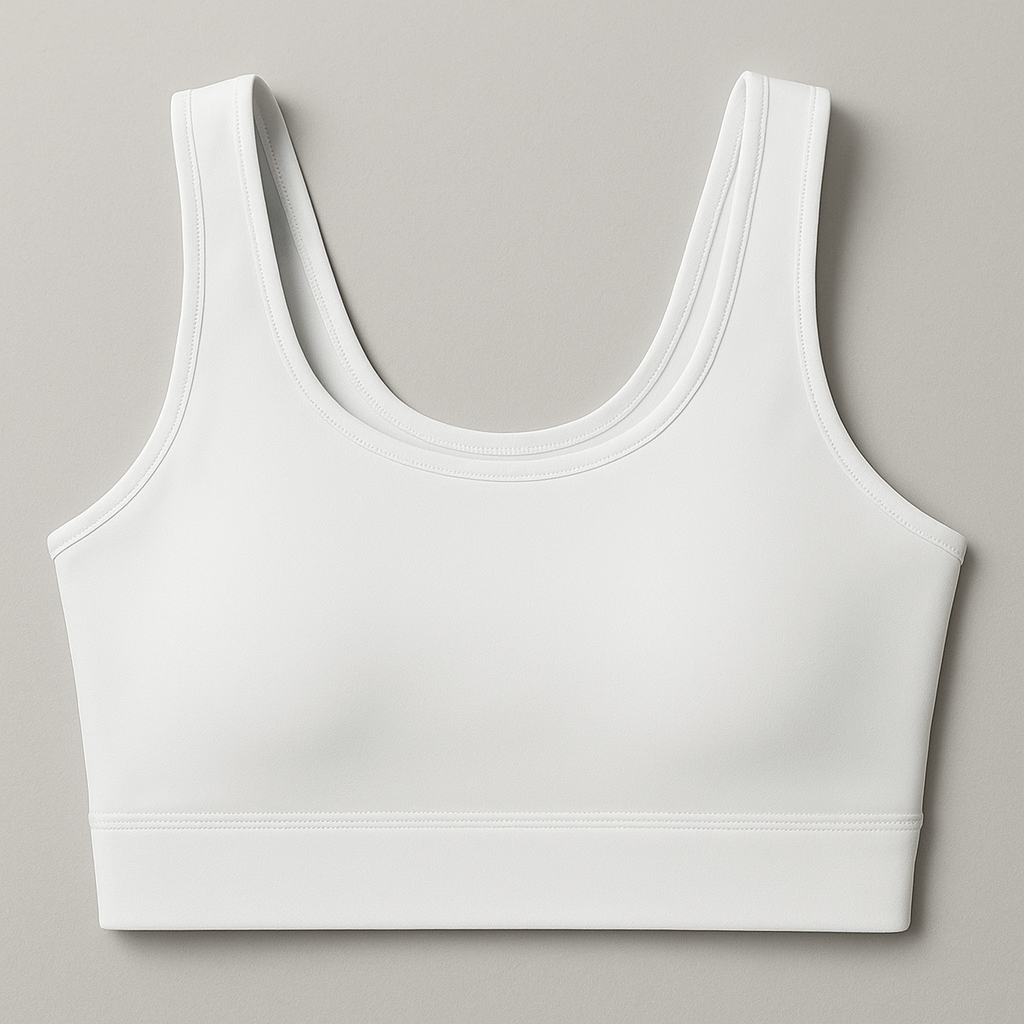

a. Compression Bras

Compression-style bras rely on a one-piece shell of high-stretch fabric that flattens the bust against the chest wall.

- Design & Performance: Ideal for low- to medium‑impact activities (e.g., yoga, barre, walking), these bras emphasize a sleek, seamless look. Minimal seaming reduces chafe points and simplifies mass production.

- Manufacturing Considerations: Since the garment is typically cut from a single knit panel and bonded or overlocked at the edges, lead times and labor costs remain relatively low. However, achieving consistent tension across sizes requires precise fabric sourcing and quality control to prevent overstretch or sag.

b. Encapsulation Bras

Encapsulation bras feature distinct cups—molded or seamed—that individually cradle each breast, offering superior shape retention and bounce control.

- Design & Performance: Suited for medium- to high‑impact sports (e.g., running, HIIT), encapsulation styles allow for sculpted silhouettes and precise support. They often include inner linings, underbands, and adjustable straps for a customizable fit.

- Manufacturing Considerations: These designs demand more complex patternmaking, multiple fabric panels (outer shell, lining, pocketing for removable cups), and increased sewing operations. While production costs and sampling cycles are higher, the end product commands a premium positioning in the market.

c. Hybrid (Compression + Encapsulation) Bras

Hybrid bras combine the best of both worlds: an outer compression layer for broad stability with inner cups or liners for individualized support.

- Design & Performance: Offering balanced control across a range of activities, hybrids cater to consumers seeking both minimal bounce and defined shape. They’re a versatile choice for brands aiming to streamline collections without sacrificing performance.

- Manufacturing Considerations: Production involves layered construction, often bonding or stitching an encapsulation liner within a compressive shell. This dual‑layer approach increases material consumption and assembly complexity, so clear tech packs and sample approvals are essential to manage cost and maintain consistent quality.

Support Levels Explained

Support levels define how well a sports bra manages movement during various activities and are typically classified as low, medium, or high impact. Each level serves a distinct purpose based on intensity and wearer needs.

- Low-Impact:

Best for yoga, stretching, or daily wear. These are usually pullover compression styles with lightweight fabrics and minimal structure. Ideal for lounge or athleisure lines due to simple construction and low production cost. - Medium-Impact:

Suited for gym workouts, cycling, or dance. These often blend compression with light encapsulation, featuring wider straps and removable padding. A balance of comfort and support, they cater to a broad consumer base. - High-Impact:

Built for running, HIIT, or team sports. These bras use molded cups, reinforced bands, and secure closures for maximum control. They require more advanced construction and are key to performance-driven collections.

Design Features and Variations

Beyond construction and support, the success of a sports bra often hinges on the finer design details that enhance fit, function, and appeal. These variations allow brands to tailor products for different markets, aesthetics, and performance expectations.

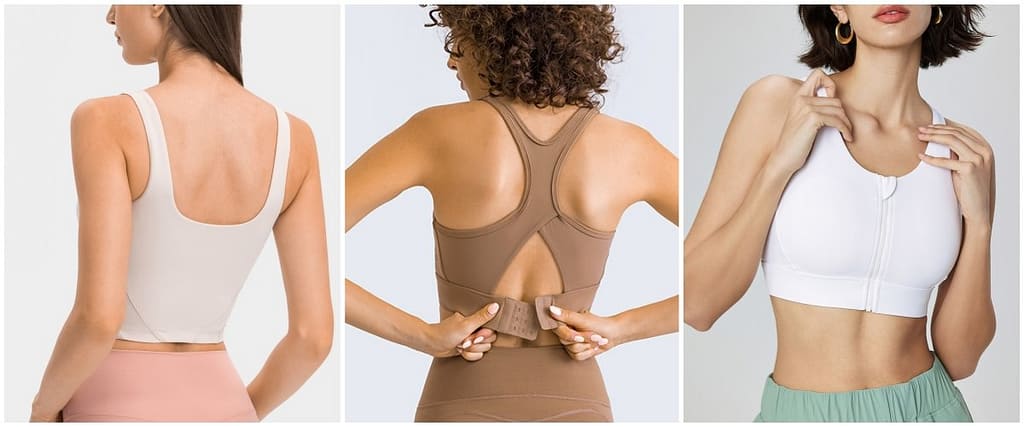

Strap Styles

- Racerback: Popular for its supportive structure and freedom of movement, especially in high-impact bras.

- Cross-back: Offers stylish appeal with added shoulder stability.

- Adjustable/Convertible: Enhances versatility and personalized fit, particularly in multi-use or premium designs.

Closures

- Pullover: Simplifies construction, commonly used in low-impact styles.

- Hook-and-eye: Adds security and adjustability, ideal for high-impact or larger cup sizes.

- Front zipper: Offers easy on/off functionality and a sleek look, often used in mid- to high-impact models.

Cups and Padding

- Removable Pads: Allow for flexible shaping and easier washing.

- Molded Cups: Provide defined shape and support, suitable for encapsulation styles.

- Unlined: Lightweight and breathable, preferred in hot climates or minimalist designs.

Additional Features

- Mesh Panels or Laser-Cut Venting: Improve breathability during workouts.

- Wide Underbands: Increase support and reduce ride-up.

- Seamless Construction: Enhances comfort and aesthetics, minimizing chafing.

Considerations for Product Development

Material Selection & Performance

- Moisture Management: Choose wicking fabrics (e.g., polyester-spandex blends) to keep wearers dry.

- Stretch & Recovery: Ensure yarns and knits regain shape after use—key for compression and durability.

- Sustainability: Evaluate recycled or eco-friendly fibers to meet growing consumer demand without sacrificing function.

Pattern Complexity & Cost

- Panel Count: More panels (as in encapsulation or hybrids) offer precision fit but increase cutting and sewing labor.

- Seam Types: Bonded seams create sleek finishes but require specialized machinery; overlocked seams are more accessible but may bulk up edges.

Sizing & Grading Strategy

- Inclusive Ranges: Define cup- and band-size increments that align with target demographics, balancing pattern complexity with market coverage.

- Fit Testing: Incorporate wear trials early to validate support levels and adjust grading rules, minimizing post-production returns.

Sampling & Prototyping

- Tech Packs: Provide clear specifications—fabric codes, trim details, stitch counts—to streamline sample accuracy.

- Iteration Cycles: Plan for 2–3 rounds of samples to refine fit, finish, and performance before bulk production.

How We Support Sports Bra Manufacturing

At GOPHERWOOD, we partner with brands and designers to bring sports bra concepts from sketch to shelf with efficiency and quality. Our full-service offerings include:

- OEM & ODM Capabilities

Whether you need end-to-end original design manufacturing (ODM) or to produce according to your specifications (OEM), we flex to your project scope and branding requirements. - Fabric Sourcing & Innovation

Leverage our global network of certified mills for high-performance and sustainable materials—moisture-wicking knits, recycled yarns, and specialty finishes like antimicrobial or UV-protection treatments. - Technical Development & Sampling

We translate tech packs into precision-driven prototypes. Our in-house patternmakers and sample room engineer sizes and constructions—compression, encapsulation, or hybrid—over multiple iterations to perfect fit and function. - Size Grading & Fit Validation

Offering extensive size ranges with graded fit blocks for band and cup increments. We coordinate wear trials and provide detailed fit reports to ensure support levels meet target activity profiles. - Trim & Hardware Integration

From custom-branded hooks and sliders to front-zip closures and performance mesh inserts, our trimming services allow you to create distinctive, market-ready sports bras. - Flexible Production Runs

Catering to startups and established labels alike, we support low minimum order quantities for small-batch collections as well as scalable lines that ramp into high-volume seasonal orders. - Quality Assurance & Compliance

Rigorous quality checkpoints throughout cutting, sewing, and finishing stages. We verify care labeling, performance claims, and regional compliance standards to mitigate risk and protect your brand reputation.

Conclusion

In the competitive activewear market, a deep understanding of sports bra styles—from core constructions and support levels to specialized niche designs—empowers brands and designers to deliver products that excel in fit, function, and fashion. By collaborating with a manufacturing partner well-versed in material technologies, pattern engineering, and scalable production processes, you can streamline development, reduce time to market, and elevate your brand’s reputation for quality.

We invite you to leverage our expertise and comprehensive services to transform your activewear vision into garments that resonate with consumers and drive business growth. Let’s work together to create the next generation of sports bras that combine comfort, support, and style—designed for the way people move today.