Introduction

Garment printing has become a cornerstone of modern fashion and custom apparel production. From bold branding on t-shirts to intricate patterns on fashionwear, the ability to apply artwork directly to fabric has revolutionized how garments are designed and manufactured.

This article explores the full spectrum of garment printing—from traditional methods to modern digital techniques. Whether for mass production or one-off custom pieces, understanding the techniques and workflows behind garment printing is essential for brands, designers, and manufacturers aiming to create impactful and durable printed apparel.

What is Garment Printing?

Garment printing refers to the process of applying designs, logos, patterns, or images directly onto finished garments or fabric panels. Unlike woven or knitted patterns that are part of the fabric structure, printed designs sit on the surface or become embedded through chemical or heat-based processes.

This decorative method is widely used across fashion, sportswear, promotional apparel, and custom clothing. It offers a fast, flexible, and often cost-effective way to personalize or brand garments. Compared to other embellishment techniques like embroidery, garment printing typically allows for more intricate, colorful, and photo-realistic designs—especially when using digital printing methods.

Common Garment Printing Techniques

The garment printing industry uses a variety of methods, each suited to different materials, design needs, and production volumes. Here are the most widely used techniques:

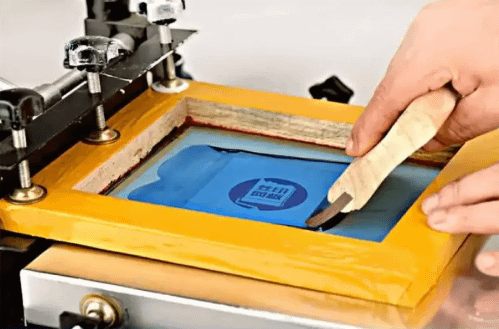

Screen Printing

One of the oldest and most popular methods, screen printing involves pushing ink through a mesh stencil onto the fabric. It’s ideal for bold, vibrant designs and large production runs due to its durability and cost-efficiency at scale.

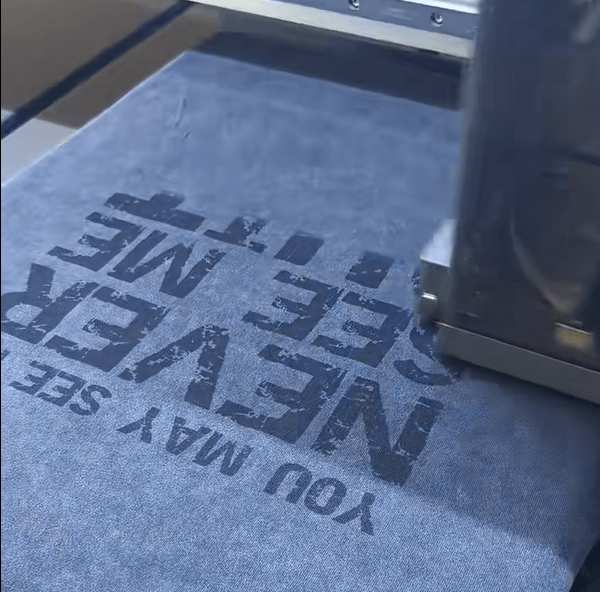

Direct-to-Garment (DTG) Printing

DTG uses specialized inkjet technology to print directly onto fabric. It’s perfect for complex, multi-colored designs and small batch orders. DTG provides excellent detail and color gradient but may not be as durable as screen printing on certain fabrics.

Heat Transfer Printing

This technique involves transferring a printed design from a carrier sheet onto the garment using heat and pressure. It includes vinyl transfer and inkjet transfer methods. It’s great for low-volume orders and personalization.

Dye Sublimation

Used mainly on polyester fabrics, dye sublimation turns dye into gas without passing through a liquid state, allowing it to bond with the fibers. The result is vibrant, all-over prints that don’t crack or peel.

Discharge Printing

Discharge printing removes the fabric’s original dye and replaces it with a new color. It works best on dark cotton garments and gives a soft, natural feel since the dye bonds directly with the fibers.

Block and Rotary Printing

Common in large-scale textile production, block printing is a manual method using carved blocks, while rotary printing uses engraved rollers. These methods are ideal for continuous patterns on long fabric rolls.

Printing Workflow: Step-by-Step

The garment printing process involves several key stages, each ensuring that the final product meets design expectations in terms of color, quality, and durability. Below is a step-by-step breakdown of the typical workflow:

| Step | Description |

|---|---|

| 1. Design Creation | Artwork is digitally prepared using graphic software. This may include color separation, sizing, and format adjustments to suit the chosen printing method. |

| 2. Fabric Selection | Choosing the right fabric (cotton, polyester, blends, etc.) that works best with the printing method, especially considering ink compatibility and garment purpose. |

| 3. Pre-Treatment | For methods like DTG or sublimation, garments often require pre-treatment to enhance ink absorption and print clarity. |

| 4. Printing | The design is applied to the garment using the selected technique—screen printing, DTG, sublimation, etc. |

| 5. Curing & Fixing | Heat pressing, drying, or chemical curing is used to set the ink and ensure wash durability. The method varies depending on the ink and fabric type. |

| 6. Quality Control | Printed garments are inspected for alignment, color accuracy, consistency, and defects before packaging and delivery. |

Choosing the Right Printing Technique

Selecting the appropriate printing method is crucial to achieving the desired outcome in terms of appearance, durability, and cost. The choice depends on several key factors:

Fabric Type

Different techniques work better on specific materials. For instance:

- Cotton is ideal for screen printing and DTG.

- Polyester works best with dye sublimation.

- Blends may require testing for compatibility and pre-treatment.

Design Complexity

- Detailed or photographic designs are best suited for DTG or sublimation due to their ability to render high-resolution prints.

- Simple graphics or logos with fewer colors are more economical with screen printing.

Order Quantity

- Large quantities benefit from the cost-efficiency of screen printing.

- Small batches or one-off pieces are better suited to DTG or heat transfer.

Production Speed

- Screen printing takes longer to set up but prints quickly in bulk.

- DTG is faster for setup but slower for printing multiple items.

Cost

- Setup costs for screen printing are higher, but the cost per piece decreases with volume.

- DTG and heat transfer have lower setup costs, making them ideal for small runs or personalized items.

Pros and Cons of Each Method

Each garment printing technique offers distinct advantages and drawbacks. Understanding these helps in making informed production decisions:

| Printing Method | Pros | Cons |

|---|---|---|

| Screen Printing | – Vibrant, long-lasting colors – Cost-effective for bulk orders | – High setup time and cost – Limited to simpler designs |

| Direct-to-Garment (DTG) | – Great for detailed, multi-color designs – No setup costs for small runs | – Slower printing speed – Works best only on cotton garments |

| Heat Transfer | – Good for custom, short-run jobs – Simple application process | – May peel or crack over time – Less breathable feel |

| Dye Sublimation | – Permanent, all-over prints – High color vibrancy | – Limited to polyester fabrics – Not suitable for dark garments |

| Discharge Printing | – Soft-hand feel – Good for vintage, muted looks | – Limited color options – Requires 100% cotton and reactive dyes |

| Block/Rotary Printing | – Efficient for repetitive patterns – Suitable for fabric rolls | – Limited design detail – Not ideal for varied or custom artwork |

Conclusion

Garment printing is a dynamic and essential part of modern apparel production, enabling everything from mass-produced fashion graphics to highly personalized, on-demand pieces. With various techniques available—each offering unique benefits—understanding their workflows and applications is key to achieving high-quality, cost-effective results.

As the industry embraces digital innovation and sustainable practices, garment printing continues to evolve, offering more flexibility, speed, and creative freedom than ever before. Whether you’re a designer, manufacturer, or brand owner, choosing the right printing approach can elevate your products and align your operations with current trends and future demands.

At GOPHERWOOD, we specialize in B2B cross-border garment manufacturing and offer advanced printing solutions tailored to your needs—whether you require bulk production or small custom runs. With low minimums, reliable delivery, and full-service support, we help brands worldwide bring their ideas to life with precision and efficiency. Partner with us to produce high-quality printed apparel that meets both your creative vision and commercial goals.