Introduction

Felt fabric stands out as one of the most versatile and oldest textiles in the world. Its soft yet sturdy structure, combined with the absence of weaving or knitting, gives it a unique place in both traditional crafts and modern ind

From children’s crafts to fashion, insulation, and even high-performance applications, felt’s adaptability continues to inspire innovation. Its non-woven composition and wide range of material choices open the door to endless creative and functional possibilities.

Origins and History

Felt is believed to be the oldest known textile, with roots tracing back thousands of years. Archaeological evidence shows that ancient civilizations in Central Asia used felt for clothing, rugs, and shelter—especially among nomadic groups who valued its warmth and portability.

One famous legend credits the discovery of felt to Saint Clement, a wandering monk who stuffed wool into his sandals to prevent blisters; the combination of moisture, heat, and pressure produced the first felt. Regardless of the exact origin, felt quickly spread across cultures—from yurts in Mongolia to ceremonial garments in Europe.

Over time, felt transitioned from a purely functional material to a staple in decorative arts, fashion, and industrial use—showcasing its lasting appeal and adaptability.

What Is Felt Fabric?

Felt is a non-woven textile made by matting, compressing, and bonding fibers together. Unlike woven or knitted fabrics, felt has no warp or weft structure—its strength and texture come from the entangled fibers themselves.

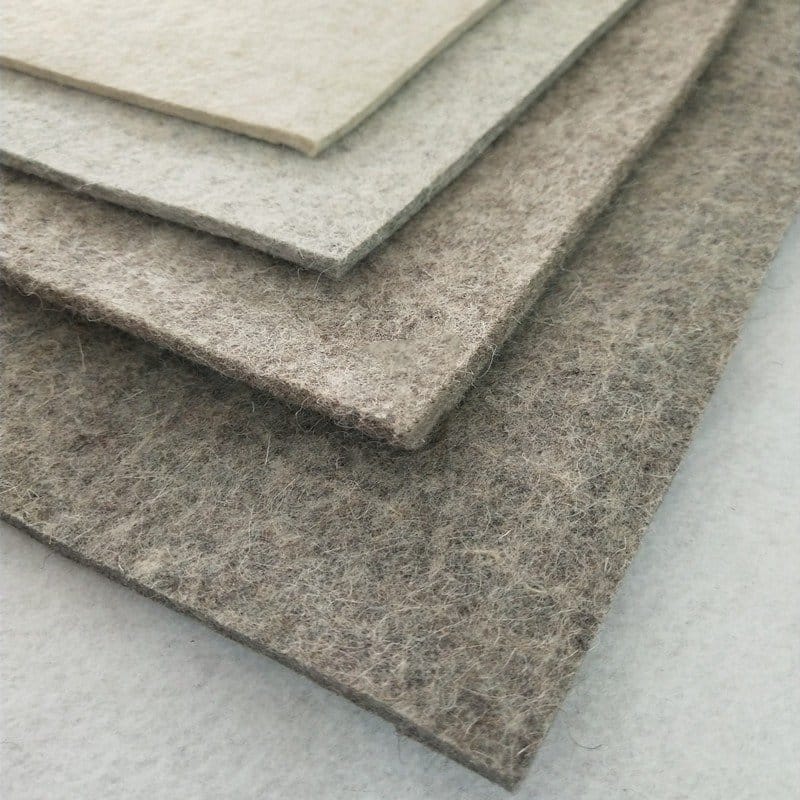

It can be made from various sources:

- Natural fibers such as wool and alpaca, which felt easily due to their scaly surface.

- Synthetic fibers like acrylic or polyester, often used for cost-effective and colorful craft felts.

- Blended fibers, which combine natural softness with synthetic durability.

There are also different felting methods—wet felting (using moisture, agitation, and heat) and needle felting (using barbed needles to entangle fibers mechanically)—each suited for specific uses. This construction method gives felt its signature thickness, density, and resistance to fraying.

Key Characteristics

Felt fabric is known for its unique structure and multifunctional qualities. Here are some of its most notable characteristics:

- Dense and Insulating

Felt’s compact fiber structure traps heat, making it an excellent insulator for both temperature and sound. - Soft Yet Firm

It has a smooth, often velvety surface with a firm body that holds shapes well—ideal for crafts, hats, and molded accessories. - Non-Fraying

Because it is non-woven, felt can be cut into shapes without unraveling, which simplifies crafting and design. - Varied Thicknesses and Colors

Felt is available in a wide range of densities, thicknesses, and vibrant hues, offering flexibility for creative or industrial use. - Moisture Absorbent

Especially with wool-based felt, the fabric can hold moisture while remaining relatively breathable.

Types of Felt Fabrics

Felt fabrics come in several types, each tailored for specific applications depending on the fibers used and the method of production:

- Wool Felt

Made from 100% natural wool, this type is warm, dense, and biodegradable. It’s commonly used in garments, crafts, and musical instruments for its natural texture and acoustic properties.

- Needle Felt

Created by mechanically interlocking fibers using barbed needles, this felt is durable and often used for industrial and decorative purposes. It has a more rigid structure and can be made from natural or synthetic fibers.

- Acrylic/Synthetic Felt

Made from polyester or acrylic fibers, this is a cost-effective and colorful option commonly used in schools, crafts, and low-cost decorative items. It’s less durable than wool but ideal for short-term or lightweight projects.

- Blended Felt

A mix of natural and synthetic fibers, blended felt balances softness, strength, and cost. It’s widely used in fashion, upholstery, and accessories where performance and aesthetics are equally important.

Production Process

Felt is produced through a process that compresses and entangles fibers into a dense, cohesive fabric. While the method can vary based on the type of felt, the essential steps are as follows:

Felt Fabric Production Process

| Step | Description |

|---|---|

| 1. Fiber Preparation | Natural (e.g., wool) or synthetic fibers are cleaned, carded (combed), and layered evenly. |

| 2. Felting | In wet felting, fibers are agitated with water, soap, and heat to cause the fibers to mat together. In needle felting, barbed needles repeatedly pierce the fibers to mechanically interlock them. |

| 3. Fulling (Wet Felting Only) | Additional pressure and moisture are applied to further condense the fibers, increasing density and strength. |

| 4. Drying | The felt is dried flat or pressed to remove moisture and lock in the fabric structure. |

| 5. Finishing | The felt may be dyed, pressed, cut into sheets, or treated to meet specific performance or aesthetic standards. |

Common Applications

Felt fabric is used across a broad range of industries and crafts due to its structure, texture, and versatility. Here are some of its most common applications:

- Fashion & Accessories

Felt is popular in making hats, shoes, handbags, brooches, and jackets. Its moldability and structure help maintain shape while offering comfort and style. - Home & Decor

Used in rugs, coasters, storage baskets, and wall panels, felt adds a warm, modern touch to interiors. Its sound-dampening quality also makes it ideal for acoustic insulation. - Crafting

Widely used in DIY projects, educational materials, and seasonal decorations, synthetic felt is favored for its bright colors and ease of cutting. - Industrial Uses

Felt is applied in automotive insulation, machinery padding, gaskets, and filtration. Its density and resistance to wear make it suitable for technical environments. - Musical Instruments

Wool felt is commonly used in pianos (hammer heads), drums (mallets), and other instruments where controlled impact and sound are essential.

Care and Maintenance

Caring for felt fabric depends largely on the t

- Cleaning

- Spot Cleaning: Gently dab stains with a damp cloth and mild soap—avoid rubbing.

- Washing: For wool felt, hand wash in cold water only if necessary. Synthetic felt may tolerate gentle machine cycles, but always check the label.

- Drying: Lay flat to dry. Avoid wringing, which can distort the shape or cause shrinkage.

- Storage

Store felt items in a dry, cool place away from direct sunlight. Keep flat or rolled to prevent creasing or deformation. - Handling Tips

Use lint rollers or fabric brushes to remove dust and fibers. Avoid excessive moisture or heat, which can damage the felt’s structure.

Conclusion

Felt fabric’s unique combination of softness, structure, and versatility has secured its place from ancient times to today’s innovative design landscapes. Its non-woven construction offers practical benefits like insulation and durability while inspiring creative uses in fashion, home decor, industry, and crafts.

As sustainability and technology shape the future of textiles, felt’s adaptability and eco-friendly potential make it a fabric with truly endless possibilities. Whether in traditional applications or cutting-edge designs, felt continues to blend function and artistry in remarkable ways.