Introduction

High-elasticity fabrics have transformed modern clothing, from activewear that hugs the body to fashion pieces designed for comfort and movement. Their stretch gives designers freedom to create sleek silhouettes without sacrificing mobility. Yet behind the smooth fit lies a hidden challenge: not all stretch fabrics can recover their shape after wear.

When rebound and recovery rates are low, garments lose their intended fit quickly—sometimes after just one try-on. The result is sagging knees, baggy waistlines, or tops that slide off the shoulders. This “fit trap” not only frustrates consumers but also affects brand reputation, making recovery a critical but often overlooked factor in fabric selection.

Understanding Fabric Recovery

At first glance, “elasticity” and “recovery” may sound like the same thing, but in textiles they represent two very different qualities. Elasticity refers to a fabric’s ability to stretch under force—think of how leggings expand when you pull them on. Recovery, however, measures how well the fabric returns to its original dimensions after that force is removed. A fabric with high stretch but poor recovery may feel comfortable at first, yet it quickly becomes loose and shapeless.

Recovery is typically expressed as a percentage, showing how close the fabric comes to regaining its original length after being stretched. For example, a recovery rate of 95% means the fabric almost snaps back completely, while 70% indicates noticeable sagging. Many designers and buyers focus on stretch percentages when sourcing fabrics, but without considering recovery, they risk choosing textiles that perform poorly in real-world wear.

Common Fit Traps in High-Elasticity Fabrics

One of the most noticeable issues is poor rebound. Fabrics may stretch effortlessly, but if the fibers don’t have the strength to return to their original state, the garment quickly loses shape. This is often seen in leggings or skinny jeans that look perfect at first but become loose at the knees and hips after a few hours.

Another trap is a low recovery rate. Even when rebound seems decent, repeated stretching—like sitting, bending, or pulling on and off—gradually weakens the fabric’s ability to return. Over time, this leads to a fit that feels slack and unsupportive. Finally, many consumers encounter looseness after trying on: garments look sharp in the fitting room but sag almost immediately after purchase, leaving the buyer with frustration and the brand with a potential return.

Technical Causes Behind Recovery Problems

- Fiber Composition

- Spandex/elastane content is the backbone of recovery.

- Low percentages (2–3%) often give initial stretch but poor rebound.

- Higher ratios (8–12%) ensure better shape retention.

- Base fibers matter: cotton absorbs moisture and weakens recovery, while polyester or nylon blends support stronger resilience.

- Yarn Structure

- Core-spun yarns (spandex at the core wrapped with other fibers) deliver superior recovery.

- Texturized yarns add comfort and volume but can sacrifice dimensional stability.

- Fabric Construction

- Knits like jersey and rib stretch easily but risk bagginess due to open structures.

- Denser constructions—double knits, interlocks, or woven stretch fabrics—are more stable and recover better.

- Finishing Treatments

- Heat setting stabilizes fabric dimensions and recovery.

- Overuse of softeners may increase comfort but reduce elasticity.

- High-heat dyeing or poor finishing can damage elastic fibers, leading to early sagging.

Each of these factors interacts with the others, meaning that recovery isn’t determined by a single choice but by how fiber, yarn, structure, and finishing are engineered together.

Quality Control & Testing Methods

Ensuring strong recovery in high-elasticity fabrics isn’t guesswork—it requires systematic checks before garments reach the market. Several methods can help identify weak points early:

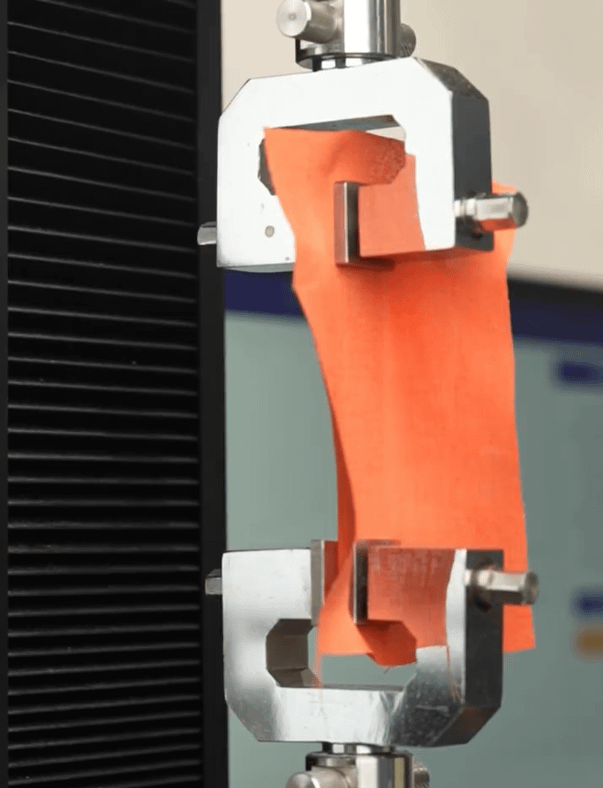

- Lab-Based Stretch–Recovery Tests

- Fabrics are stretched to a set percentage (e.g., 50% elongation) and then released.

- The recovery rate is measured after a fixed time, showing how close the fabric returns to its original dimensions.

- Multiple cycles simulate real-world wear, revealing long-term performance.

- Elongation and Fatigue Testing

- Measures how far a fabric can stretch before deformation.

- Fatigue tests stretch and release fabrics repeatedly, mimicking bending, sitting, or dressing motions. Poor fabrics show permanent growth after only a few cycles.

- Simple In-House Checks

- Designers or manufacturers can stretch a fabric swatch by hand and observe whether it snaps back cleanly.

- Hanging weight tests—where fabric samples hold small weights—can reveal if the material grows or sags under pressure.

- Benchmarks and Standards

- Industry often targets recovery rates above 90–95% for premium performance fabrics.

- For everyday garments, slightly lower rates may be acceptable, but anything under 80% risks consumer dissatisfaction.

Design & Production Solutions

Addressing fit issues in high-elasticity fabrics requires thoughtful choices throughout design and production. Key strategies include:

- Fiber Blending

- Optimize spandex/elastane content to balance stretch and recovery.

- Combine with fibers like polyester or nylon to reinforce resilience without sacrificing comfort.

- Fabric Weight and Density

- Heavier fabrics or denser knits can better resist sagging.

- Avoid overly thin constructions that stretch easily but fail to rebound.

- Cutting and Pattern Adjustments

- Slightly tighter cuts in stretch garments compensate for expected growth during wear.

- Strategic seam placement and reinforcement in high-stress areas (knees, elbows, waistband) maintain shape over time.

- Pre-Stretching and Heat Setting

- Applying controlled pre-stretch during production stabilizes the fabric.

- Heat setting locks fibers in place, improving recovery for multiple wears and washes.

By combining smart fiber choices, construction techniques, and pattern design, brands can significantly reduce the risk of baggy or loose garments while keeping the comfort and flexibility that high-elasticity fabrics promise.

Conclusion

High-elasticity fabrics offer unparalleled comfort and freedom of movement, but without proper recovery, that initial appeal can quickly fade. Poor rebound, low recovery rates, and looseness after trying on are not just minor annoyances—they directly impact fit, wearer satisfaction, and brand reputation.

Understanding the interplay between fiber composition, yarn structure, fabric construction, and finishing treatments is essential for designers and manufacturers. Coupled with rigorous quality control and thoughtful production techniques, these insights ensure garments maintain their intended fit over time.

As a cross-border clothing manufacturer, GOPHERWOOD specializes in high-quality garments that balance comfort, stretch, and long-lasting fit. Partnering with us means access to fabrics and designs engineered to maintain shape, ensuring your collections meet the highest standards of performance and customer satisfaction.