Introduction

Cutting and sewing are two key processes in garment construction, each playing a vital role in creating well-made clothing. Cutting involves shaping the fabric, while sewing brings the pieces together. Although distinct, these processes are deeply interconnected, with precision in one directly impacting the success of the other. Understanding their relationship is essential for producing garments that are both functional and stylish.

The Role of Cutting in Garment Construction

Cutting is the foundational step in garment construction, as it shapes the fabric into the required pieces that will be sewn together to form the final garment. This stage requires both precision and careful planning, as any inaccuracies in cutting can affect the garment’s fit, appearance, and overall quality. Cutting involves not just the physical process of trimming fabric, but also the strategic arrangement of pattern pieces on the fabric to minimize waste and optimize the design.

Understanding thImportance of Fabric Preparatione Cutting Process

The cutting process begins once the fabric is prepared, typically through washing or pressing to remove wrinkles and shrinkage. Once the fabric is ready, it is laid flat, and patterns (templates of the garment pieces) are carefully positioned on it. Each pattern piece corresponds to a different section of the garment, such as the front, back, sleeves, and collar.

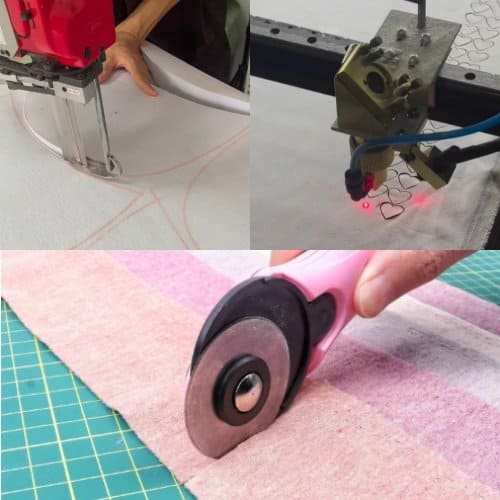

The cutting process is done either manually or with machines, depending on the scale of production:

- Manual Cutting: In smaller-scale production or with delicate fabrics, patterns are traced onto the fabric with chalk or markers before being cut by hand using scissors or rotary cutters. This method requires a high level of skill and experience to ensure accuracy.

- Automated Cutting: In industrial settings, fabric is often cut with the help of advanced machinery, such as laser cutters or automated cutting machines. These machines offer higher precision and efficiency, particularly in mass production.

Importance of Fabric Preparation

Before cutting begins, fabric must be carefully prepared to ensure accurate cutting. This includes:

- Fabric Alignment: The fabric must be aligned correctly, especially with woven fabrics, to ensure the pattern is cut along the grain of the fabric (warp and weft). Misalignment can lead to stretching or distortion, which affects the fit of the garment.

- Grainlines and Bias: Pattern pieces are usually marked with grainlines that indicate the direction of the fabric’s weave. Cutting along the grain ensures the garment holds its shape and drape. Cutting across the grain, or on the bias (diagonal direction), gives the fabric more stretch and drape, which is often used in designs for a looser fit or more fluid appearance.

Tools Used for Cutting

The tools chosen for cutting fabric can significantly affect the quality and efficiency of the process. Some of the most commonly used tools include:

- Cloth cutting scissors: Usually used to cut smaller parts or complex shapes. Manual cutting is not very efficient but has high precision.. However, they can become blunt with use and may cause inaccurate cuts.

- Rotary Cutters: These are ideal for cutting straight lines and are especially useful when cutting multiple layers of fabric. They create clean edges and minimize fabric distortion.

- Laser Cutters: Used in high-end manufacturing, laser cutters offer extremely precise cutting, especially with delicate or synthetic fabrics. They also seal the fabric edges, preventing fraying.

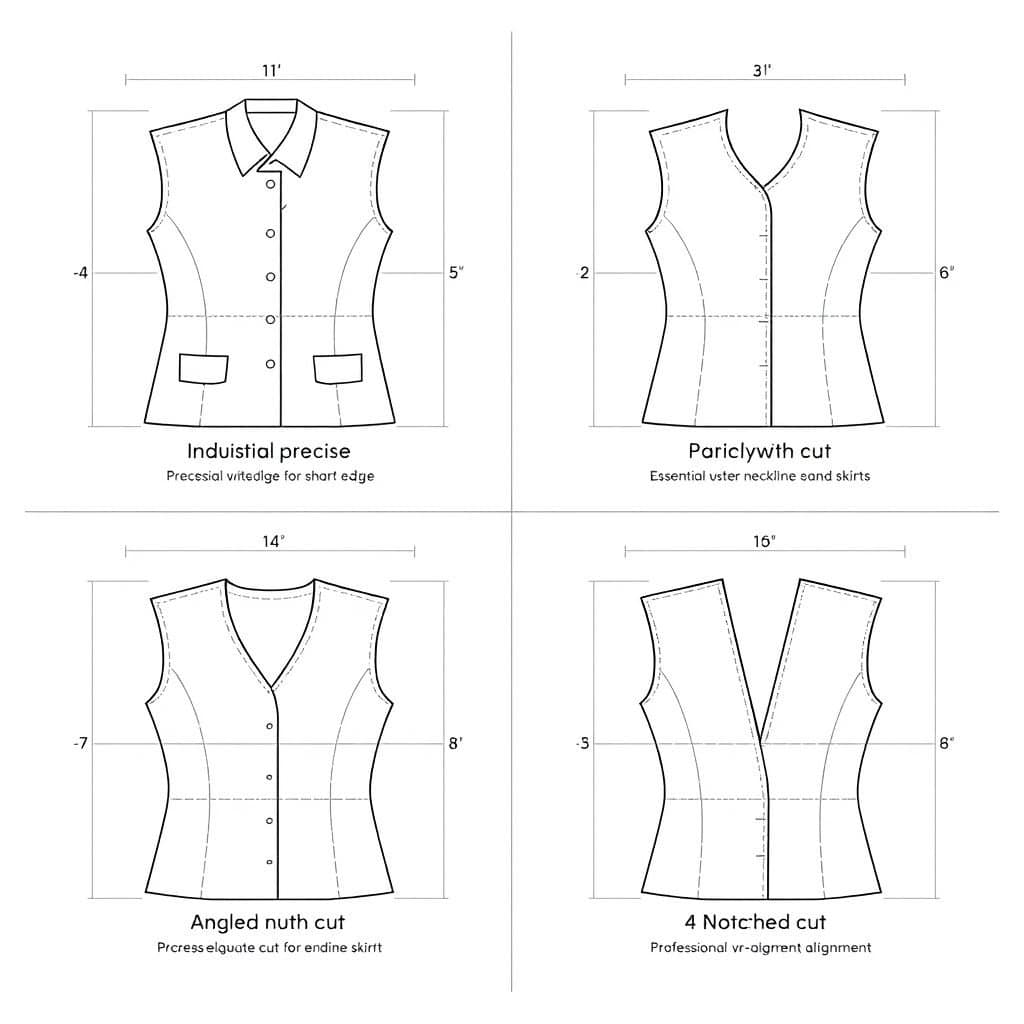

Types of Cuts

The type of cut required for a garment depends on the design and the fabric being used. Some common types of cuts include:

- Straight Cuts: These are typically used for simple shapes like straight skirts, trousers, and basic blouses. Straight cuts are easier to make, especially when cutting with rotary cutters or machines.

- Curved Cuts: For more complex shapes, such as armholes, necklines, or sleeve caps, curved cuts are necessary. These cuts require more precision to ensure the proper fit and flow of the garment.

- Angle Cuts: Angles are often used in tailoring for design elements like pleats, darts, or to create a tapered silhouette. These cuts require careful measurement to ensure they align with the overall design.

- Notches: Small “V”-shaped cuts on the edges of pattern pieces, called notches, are used to align pieces correctly during the sewing process, particularly on curves and corners.

Challenges in Cutting

While cutting may seem straightforward, it presents several challenges that require expertise:

- Fabric Stretch: Stretch fabrics like knits or jerseys require special care during cutting to avoid distortion. They need to be cut on the grain or bias to ensure the garment fits well without losing its shape.

- Delicate Fabrics: Fabrics like silk or chiffon are more prone to fraying and shifting during cutting. These require extra care in handling, and sometimes stabilizing agents (such as tissue paper) are used to maintain shape.

- Layered Cutting: When cutting multiple layers of fabric, it’s essential to ensure that each layer is aligned and that no fabric shifts, which could result in uneven pieces. Using weights or pins can help keep the layers in place.

The Role of Sewing in Garment Construction

While cutting forms the building blocks of a garment, sewing is the process that brings those individual pieces together to create a finished product. It’s the act of stitching the fabric pieces into a cohesive whole, providing structure, shape, and durability. Without effective sewing, even the most meticulously cut fabric pieces would remain as loose fragments, unable to function as wearable garments.

Understanding the Sewing Process

Sewing in garment construction involves more than just connecting pieces of fabric. It is a meticulous process that includes choosing the right stitching technique, maintaining proper seam allowances, and ensuring the garment fits as intended. The quality of stitching is directly linked to both the garment’s appearance and its longevity. Inaccurate or inconsistent stitching can lead to issues like seam puckering, loose seams, or garments that fall apart after minimal wear.

The sewing process typically follows these stages:

- Pinning and Basting: Before stitching, the fabric pieces are often pinned or basted (temporarily stitched) together to hold them in place. This ensures that they remain aligned while sewing, especially with complex seams or curves.

- Sewing the Seams: Seams are the most basic element in garment construction, as they join the fabric pieces. The sewing machine’s needle and thread move through the fabric, binding the pieces together.

- Finishing: After the seams are sewn, the edges may need to be finished to prevent fraying and to reinforce the durability of the garment. Techniques like overlocking or using pinking shears are employed to secure raw fabric edges.

Basic Sewing Techniques

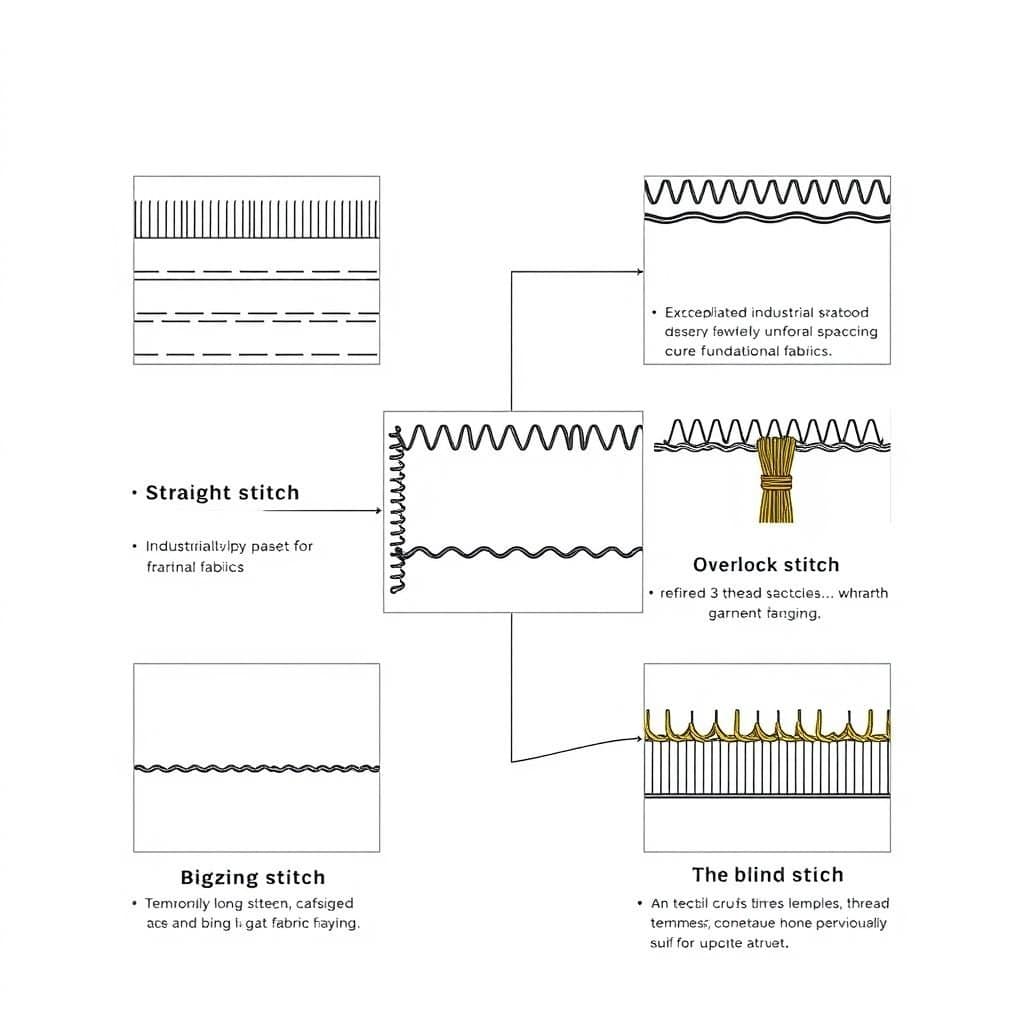

The choice of sewing technique varies based on the type of garment, fabric, and design. Here are some common sewing techniques:

- Hand Sewing: Although machine sewing dominates most garment construction, hand sewing remains essential for delicate tasks such as hemming, attaching buttons, or adding finishing touches. It allows for greater precision and control, especially in smaller, more intricate areas of the garment.

- Machine Sewing: Machine sewing is faster and more efficient for larger projects, especially in commercial settings. It includes several stitching methods:

- Straight Stitch: The most common stitch used for joining seams. It’s simple and effective for most fabrics.

- Zigzag Stitch: This stitch helps prevent raw edges from fraying, and it’s especially useful when working with stretch fabrics.

- Overlock Stitch: Also known as a serger stitch, this is commonly used in knitwear and woven fabrics to finish edges and prevent them from unraveling.

- Basting Stitch: A temporary, long, and loose stitch used to hold fabric pieces together before permanent stitching.

- Blind Hem Stitch: This stitch is used for hemming without showing visible stitching on the outside of the garment, often used for trousers, skirts, and formal wear.

Sewing Techniques and Their Impact

Sewing involves a range of techniques that not only join fabric but also influence the garment’s fit, style, and functionality. Some key aspects include:

- Joining Fabric Pieces: The alignment of fabric pieces during sewing is crucial. Proper seam allowances (the fabric space between the edge and the stitching) are essential to ensure the garment fits as designed. If seam allowances are too narrow or uneven, it can cause the garment to be too tight or ill-fitting.

- Sewing Curves and Corners: Curved seams, such as armholes or necklines, require extra attention. It’s important to clip or notch the seam allowances to allow the fabric to curve smoothly without puckering.

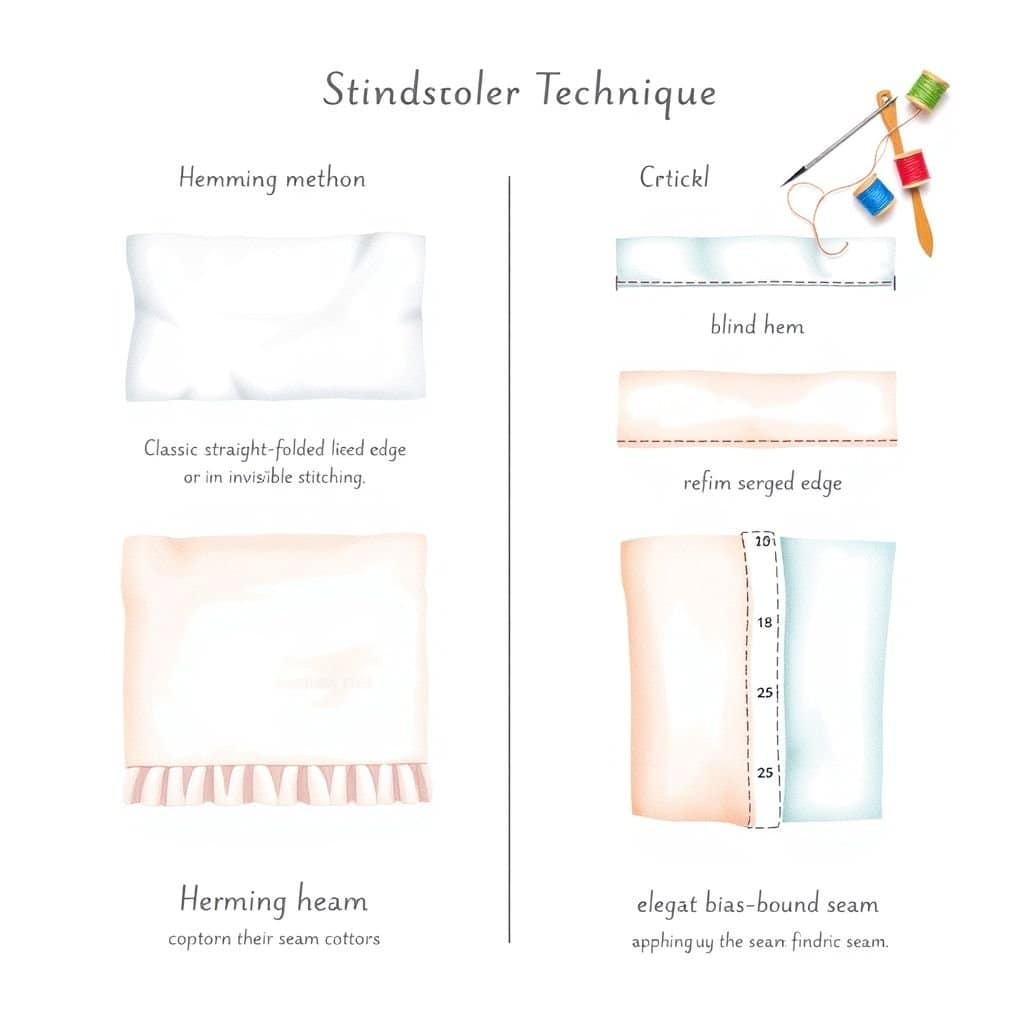

- Hemming: Hemming is one of the final sewing steps, where the edges of fabric pieces are folded over and stitched to prevent fraying and give the garment a polished look. Hemming can vary from simple straight hems to more decorative finishes like blind hems or rolled hems.

- Finishing Seams: Properly finishing seams is essential for durability, especially in fabrics prone to fraying. Techniques like overlocking, French seams, or bound seams help secure edges and prevent the fabric from unravelling over time. This is especially important in garments that will undergo frequent washing.

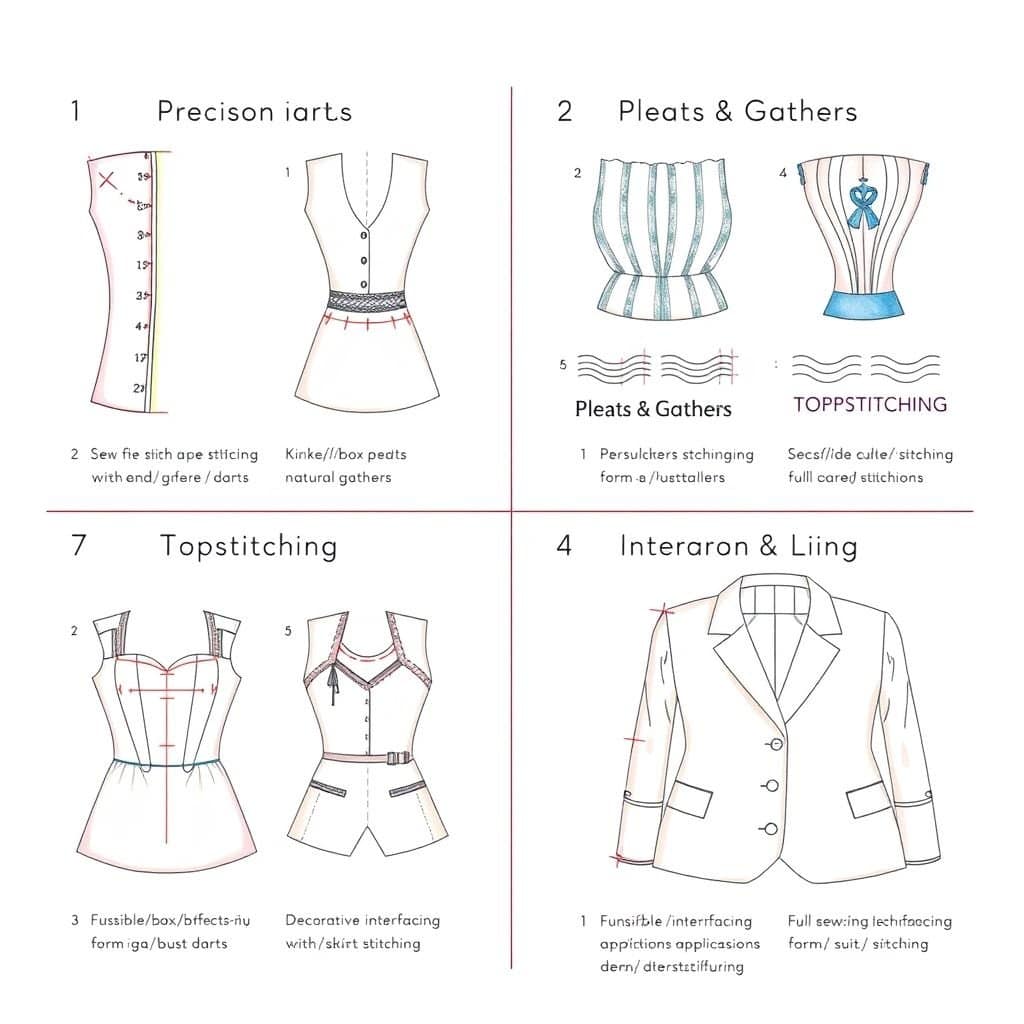

Advanced Sewing Techniques

For high-quality, professionally constructed garments, additional techniques may be employed:

- Darting: Darts are sewn into garments to provide shaping and structure, particularly in areas like the bust or waist.

- Pleating and Tucking: These techniques are used to add texture, volume, and design interest to garments.

- Topstitching: This is often done for decorative or functional purposes, like reinforcing collar edges or hems.

- Interfacing and Underlining: These are techniques used to add structure to certain parts of the garment, such as collars, cuffs, or waistbands.

Challenges in Sewing

Sewing requires precision, and several factors can present challenges during the process:

- Fabric Behavior: Different fabrics have distinct properties that affect how they should be sewn. Stretch fabrics require a different set of techniques and stitches compared to woven fabrics, while delicate fabrics like silk or lace need more careful handling to avoid damage.

- Machine Settings: Adjusting the sewing machine’s tension, stitch length, and needle type is essential to accommodate the fabric and the desired stitch. Incorrect machine settings can lead to puckering, skipped stitches, or thread breakage.

- Seam Alignment: Keeping seams aligned, especially on curves or across multiple layers, is essential to ensure the garment maintains its intended shape and fit.

The Interplay Between Cutting and Sewing

While cutting and sewing are separate processes, their success relies heavily on how they complement each other. The quality of the cutting directly influences the sewing stage, and vice versa. A perfectly cut pattern is essential for accurate stitching, while the type of stitch and technique used in sewing can affect how well the cut fabric pieces come together. Understanding the relationship between these two steps is crucial for ensuring the final garment fits, performs, and looks as intended.

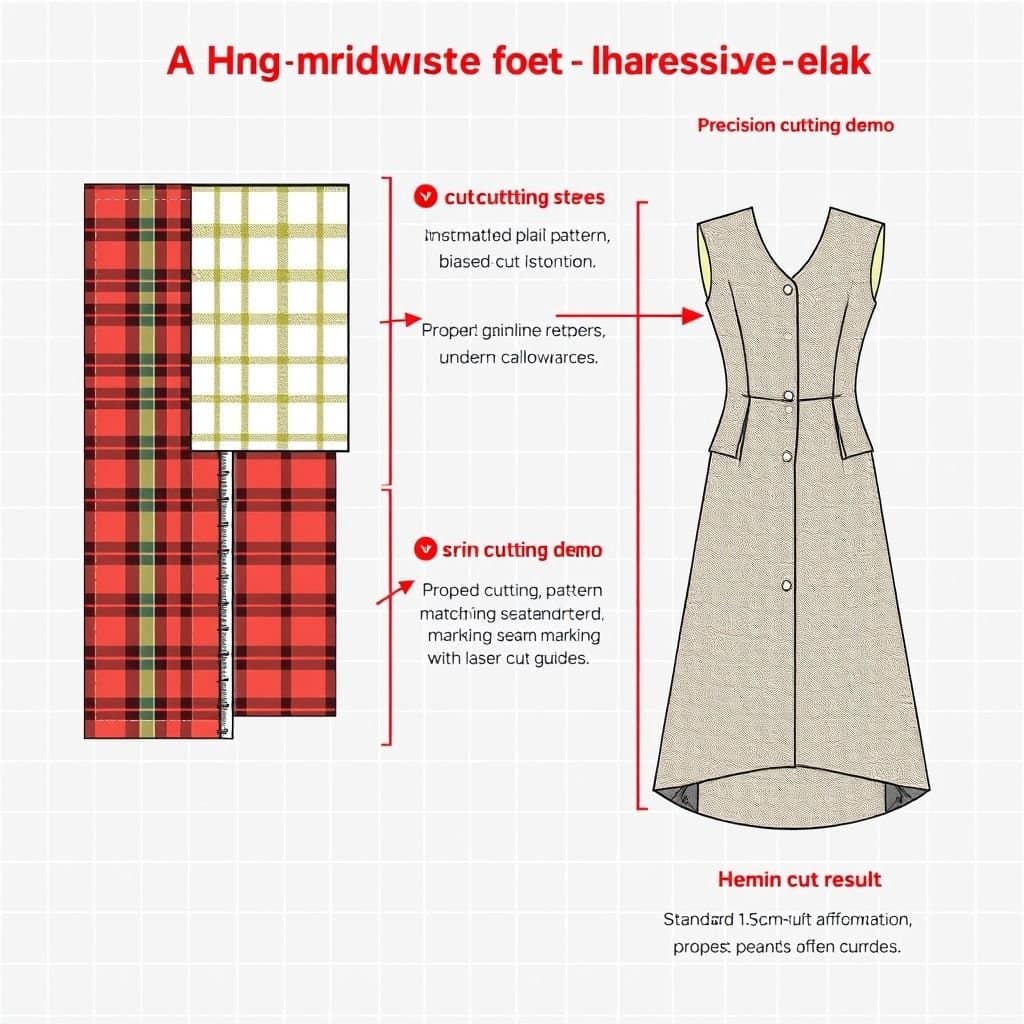

How Cutting Affects Sewing

The accuracy of the cutting process plays a significant role in how easily the sewing process will proceed. If the fabric is cut improperly, it can result in uneven seams, misaligned patterns, or poor fit. Additionally, incorrect cutting techniques can lead to fabric stretching or shifting, which complicates the sewing process.

- Pattern Matching: Proper cutting ensures that patterns, especially those with prints, plaids, or stripes, align correctly. If the fabric isn’t cut properly, the patterns may not match at the seams, resulting in a mismatched or sloppy appearance.

- Grainline and Bias: Cutting along the fabric’s grainline ensures that the garment retains its shape and structure. If pieces are cut on the bias (diagonal to the grain), it affects the garment’s stretch and drape, which can change how the garment fits once sewn. These nuances in cutting influence how the garment behaves in the sewing process, particularly around curved seams or hems.

- Seam Allowances: The width of the seam allowance (the area between the edge of the fabric and the stitching line) is determined during the cutting stage. If seam allowances are too narrow or inconsistent, it can lead to uneven sewing, distorted seams, or misfitting garments.

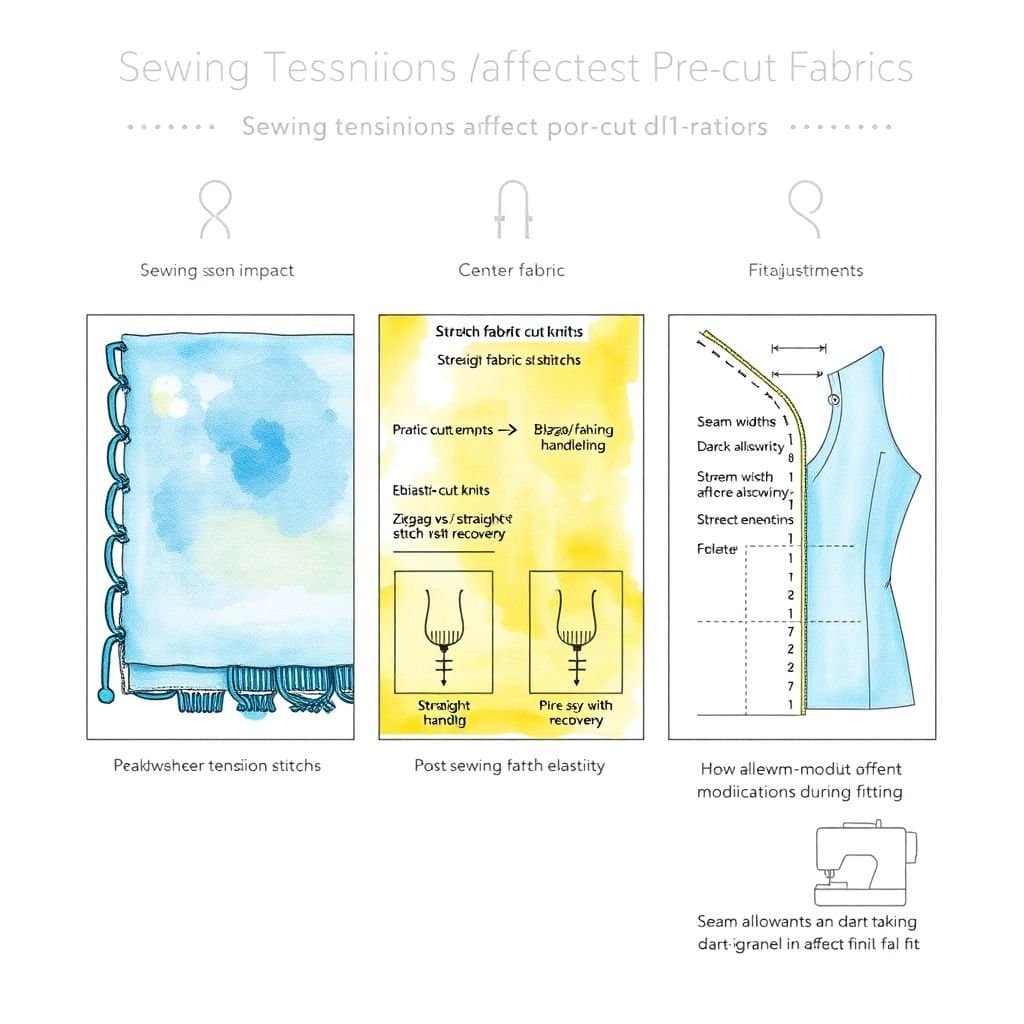

How Sewing Affects the Cutting Process

The sewing process also plays a role in how the fabric behaves after cutting. Some sewing techniques can impact the final appearance and structure of the garment, requiring adjustments in how the fabric was cut.

- Seam Allowances and Fitting: Sewing too close to the edge or deviating from the intended seam allowance can affect the final fit of the garment. While cutting establishes the base dimensions of the pieces, sewing shapes and refines the fit by taking in excess fabric or allowing for more room where necessary.

- Stretch Fabrics: When sewing stretch fabrics like knits, the stitching technique used (such as a zigzag or stretch stitch) will impact how well the fabric holds its shape and elasticity. If a fabric is cut on the bias and then sewn incorrectly, it can stretch or distort, leading to garments that lose their shape over time.

- Fabric Tension and Stitching: The tension applied during sewing, combined with the way the fabric is handled, can change the way the fabric drapes. If the fabric is stretched or manipulated too much during sewing, the cut pieces may no longer align correctly, leading to puckering or distortion.

Coordinating Cutting and Sewing for Seamless Construction

Achieving a seamless transition between cutting and sewing is an art that requires careful coordination and expertise in both disciplines. To ensure smooth and efficient garment construction, manufacturers often work with both cutting and sewing technicians to ensure that each stage complements the other.

- Pre-Sewing Planning: In both small-scale and mass production, pre-sewing planning is essential. This includes ensuring all fabric pieces are cut correctly and uniformly, and that the proper tools and techniques are chosen for sewing. A clear understanding of how the garment will be sewn (e.g., straight seams vs. curved seams) helps inform how the pieces are cut.

- Pattern Adjustment: After sewing a sample garment, adjustments are often made to the patterns based on how the fabric reacts during the sewing process. These changes might include adjusting seam allowances, resizing pattern pieces, or modifying cuts to account for how fabric behaves once sewn.

- Fit and Refinement: Once the garment is sewn, a fitting session may be required to determine if further alterations to the pattern or cutting process are necessary. This ensures the garment meets fit and comfort specifications. Adjustments could include modifying the shape of a hem or refining the seam placement to ensure the fabric behaves as intended.

Challenges and Solutions in Cutting and Sewing

Both cutting and sewing present unique challenges that require careful planning, skill, and attention to detail. Whether it’s dealing with tricky fabrics, ensuring pattern accuracy, or managing production timelines, manufacturers often face a variety of obstacles in garment construction. However, there are proven solutions and strategies to overcome these challenges and improve the overall process.

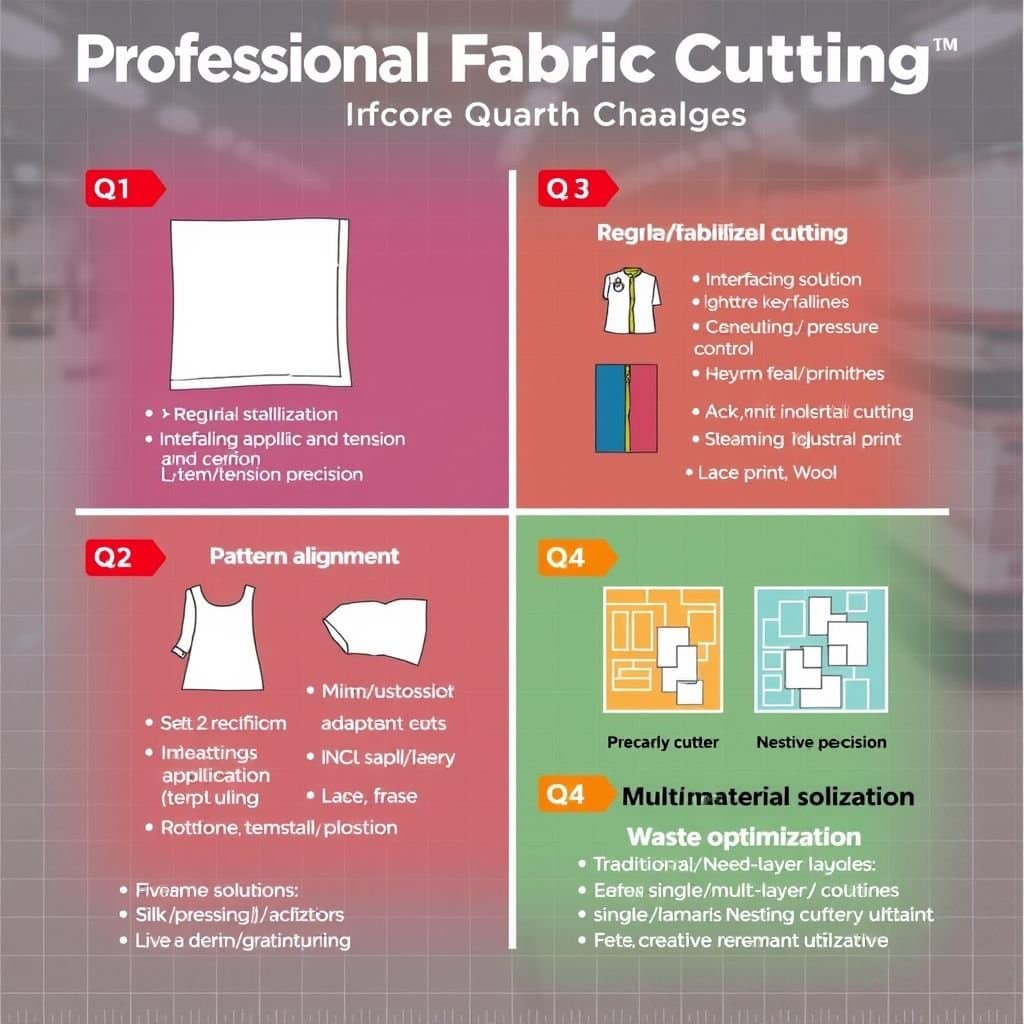

Challenges in Cutting

Fabric Stretching and Distortion:Some fabrics, especially knits or lightweight materials, can stretch or distort during the cutting process. This can lead to inaccurate pieces, misaligned patterns, or a final garment that doesn’t hold its shape.

- Solution:To avoid fabric stretching, it’s essential to handle fabrics gently during the cutting stage. For stretchy fabrics, it may be necessary to stabilize them by using fusible interfacing or cutting them while they are under slight tension. Additionally, using a rotary cutter or laser cutter can ensure cleaner, more accurate cuts without the risk of distortion.

Pattern Alignment:Aligning patterns, particularly those with prints, stripes, or plaids, can be difficult. Misalignment often leads to mismatched seams, especially around the chest, side seams, and sleeves.

- Solution:Careful pattern placement is key. Using pattern weights and making sure the grainline is respected will help align the fabric properly. For printed fabrics, ensuring that the print is aligned at specific points before cutting is crucial to achieving the desired look.

Fabric Type Variations:Different fabrics behave differently when cut. For instance, slippery fabrics like silk or satin can be challenging to cut accurately, while heavy fabrics like denim can be tough on scissors and cutting machines.

- Solution:Choosing the right cutting tool for the fabric is essential. For delicate fabrics, using a fine, sharp pair of fabric scissors can make a difference. In contrast, industrial cutting machines with high power and precision are recommended for thicker materials. Additionally, some fabrics may need to be ironed or stabilized before cutting to prevent shifting.

Fabric Waste:Cutting large amounts of fabric for garment production can often result in waste, especially when dealing with patterned fabrics or complex designs.

- Solution:Advanced software programs that optimize fabric layout can help reduce waste by planning the most efficient use of fabric. For example, markers (pre-made fabric layouts) can be optimized for the least amount of waste, and cutting in a single layer, rather than stacking fabric, can also help reduce errors.

Challenges in Sewing

Fabric Slippage and Shifting:When sewing lightweight or slippery fabrics (like satin, chiffon, or silk), the fabric tends to slip or shift under the presser foot, which can distort seams and affect alignment.

- Solution:Using specialized presser feet, such as walking feet or Teflon feet, helps prevent fabric shifting. Additionally, using tissue paper or stabilizer underneath the fabric during the sewing process can provide extra grip and reduce slippage.

Inconsistent Seams and Stitching:Uneven seams or mismatched stitching can occur when there is tension inconsistency in the sewing machine, leading to puckered or loose seams, especially in stretchy fabrics.

- Solution:Regular maintenance of the sewing machine, including checking the tension, using the right needle, and ensuring thread consistency, can help prevent these issues. It’s also useful to sew test swatches of the fabric before beginning the actual garment to ensure the machine settings are correct.

Breaking Needles and Thread Snapping:Sewing through tough or dense fabrics can sometimes result in broken needles or snapped threads, which disrupt the flow of production and require time-consuming repairs.

- Solution:Using the correct type of needle for the fabric is key. For heavier fabrics, using larger, stronger needles can prevent breakage. Similarly, choosing a stronger, more durable thread, such as polyester, for heavy fabrics or seams that require durability is also important.

Fabric Shrinking and Stretching:During the sewing process, some fabrics may shrink or stretch, especially if they’re not pre-washed or pre-shrunk. This can cause issues in achieving the correct fit and alignment.

- Solution:Pre-washing and pressing fabrics before cutting and sewing is a good practice to reduce shrinkage. Additionally, using fabrics that have been treated to prevent shrinkage (like pre-shrunk cotton) can minimize these issues.

Advancements in Cutting and Sewing Technology

The world of garment production has undergone significant technological advancements, especially in the areas of cutting and sewing. These innovations have not only enhanced efficiency but also improved the quality of the final product, reduced waste, and allowed manufacturers to meet the growing demand for fast fashion without compromising on precision.

Technological Advancements in Cutting

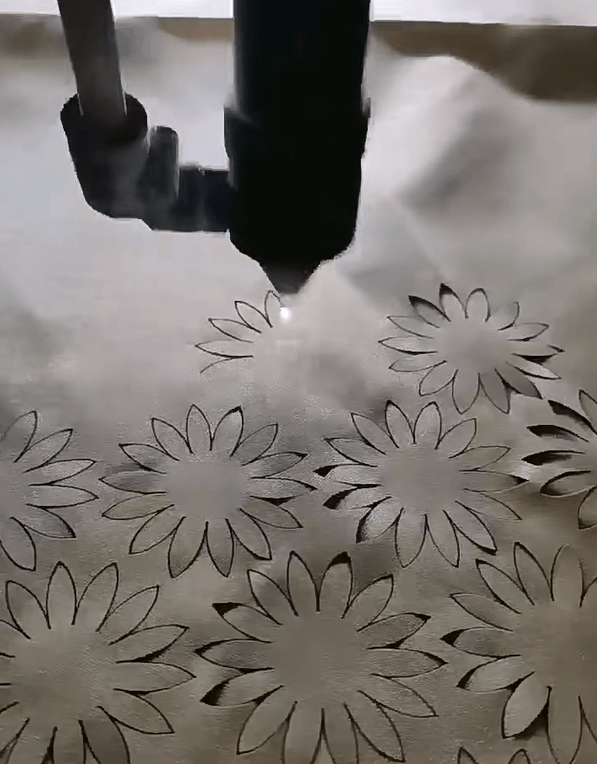

Laser Cutting

Laser cutting technology uses high-powered lasers to cut through fabrics with extreme precision. This method is particularly effective for intricate patterns, small details, and fabrics that are difficult to cut with traditional methods.

Benefits:

- High precision and accuracy.

- Minimal fabric distortion.

- Ideal for complex designs and delicate fabrics.

- Reduces fabric waste due to optimized layout planning.

Limitations:

- High initial investment cost.

- Requires specific technical expertise to operate.

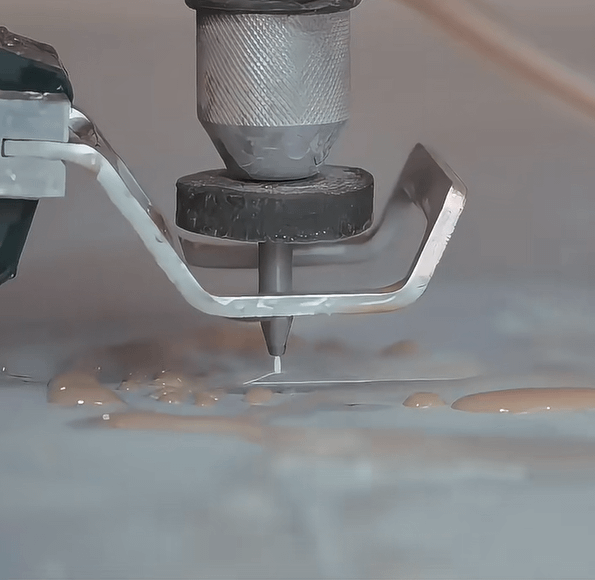

Water Jet Cutting

This cutting technique uses high-pressure water streams, often combined with abrasive materials, to cut through fabrics. It’s particularly beneficial for cutting thick or multilayered materials.

Benefits:

- Clean cuts with minimal fraying.

- No heat, reducing the risk of fabric shrinkage or melting.

- Versatile for use with various materials.

Limitations:

- Slower than laser cutting.

- Requires specialized equipment and maintenance.

Computerized Cutting Machines (CNC)

These machines are computer-controlled and can automate the cutting process with a high degree of accuracy. CNC machines can handle large volumes of cutting with consistent results.

Benefits:

- Consistent and accurate cuts.

- High speed, suitable for mass production.

- Reduces human error and material waste.

Limitations:

- Expensive to install and maintain.

- Limited flexibility for custom or small-batch production.

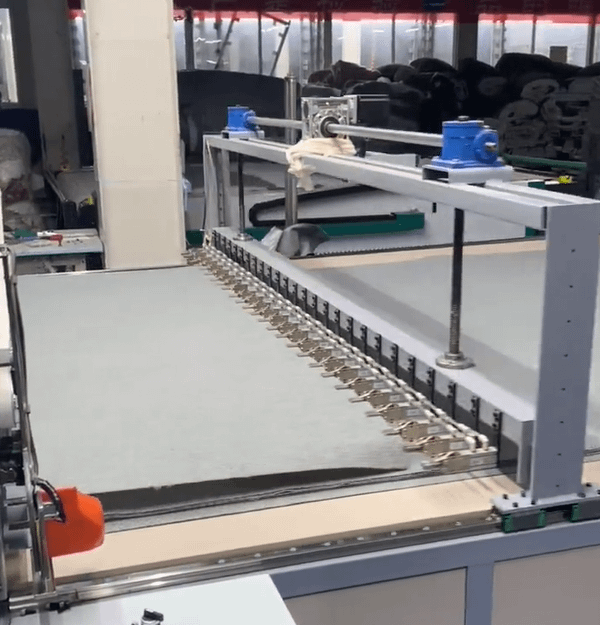

Automatic Fabric Spreading

To ensure efficient use of fabric, automated fabric spreading systems lay out fabric layers in a precise and uniform manner before cutting. This reduces the need for manual labor and helps optimize fabric usage.

Benefits:

- Increases cutting efficiency.

- Reduces human labor and inconsistencies.

- Prevents fabric slippage during the cutting process.

Limitations:

- High upfront cost.

- Requires space and specialized setup.

Technological Advancements in Sewing

Automated Sewing Machines

Automated sewing machines are designed to perform repetitive stitching tasks with minimal human intervention. These machines can handle tasks such as straight stitching, buttonholes, and even complex embroidery.

Benefits:

- Speed and efficiency.

- Consistent stitch quality.

- Reduces labor costs and production time.

Limitations:

- High initial cost and maintenance.

- Limited flexibility for highly customized designs.

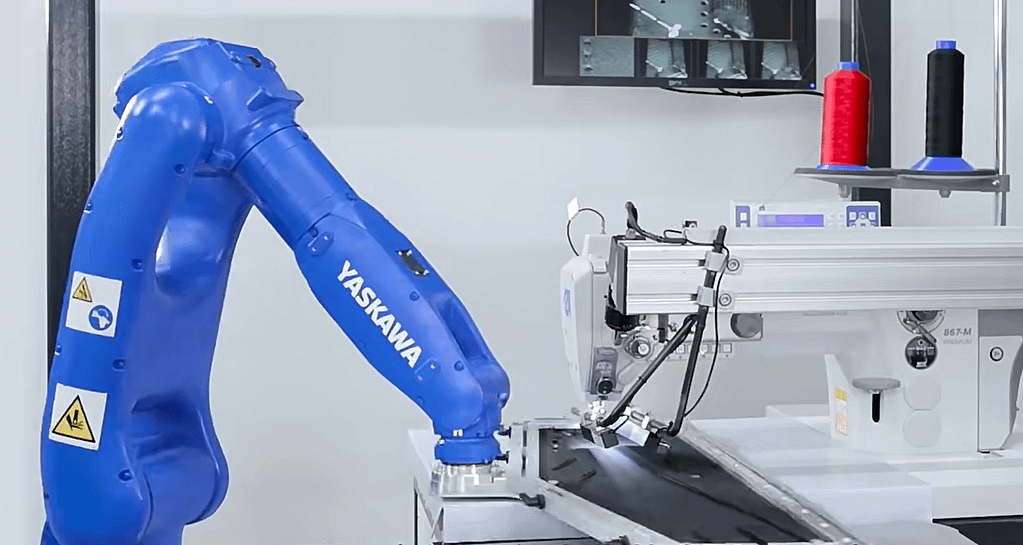

Robotic Sewing Systems

Robotic sewing systems integrate robotics with sewing machines to automate tasks like sewing, cutting, and assembling garment parts. These systems are particularly useful for large-scale production of basic designs.

Benefits:

- High speed and accuracy.

- Reduces manual labor and costs.

- Ideal for high-volume production.

Limitations:

- Expensive investment.

- Not suitable for intricate or custom designs.

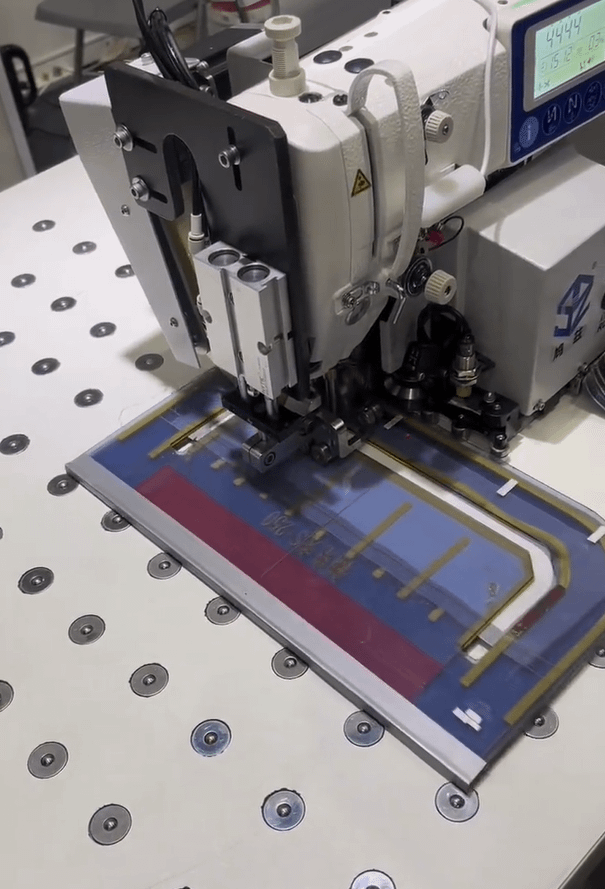

Sewing Machine with Laser Alignment

These machines use lasers to align fabric pieces with pinpoint accuracy, ensuring that seams and stitching are placed exactly as intended. This is particularly beneficial for patterns that require precise alignment, such as checks or stripes.

Benefits:

- Increased alignment precision.

- Reduces errors in pattern matching.

- Faster than traditional manual alignment.

Limitations:

- Requires advanced setup and training.

- Can be costly for smaller operations.

3D Knitting Technology

Although traditionally associated with knitting, 3D knitting technology has expanded into garment production as a whole. It can create garments with no seams, reducing the need for conventional sewing altogether.

Benefits:

- Eliminates the need for seams, reducing labor and material waste.

- Allows for highly customized garments and on-demand production.

- Faster production process.

Limitations:

- Limited to specific fabric types.

- Requires specialized equipment and training.

Conclusion: The Symbiotic Relationship Between Cutting and Sewing

The cutting and sewing processes are integral to garment production, each playing a crucial role in transforming raw fabric into a finished garment. Cutting defines the shape and structure, while sewing brings those pieces together, ensuring proper fit and durability. Together, these steps create garments that are not only functional but also visually appealing and well-constructed.

Technological advancements have greatly influenced both processes, enhancing efficiency, precision, and sustainability. The cutting process has evolved with innovations that reduce waste, while sewing has seen the rise of automation and smart machines, improving both speed and accuracy. As these technologies continue to develop, the garment industry is moving toward a future of faster, more sustainable, and customizable production.

By understanding the vital relationship between cutting and sewing, manufacturers, designers, and consumers alike gain a deeper appreciation for the complexity behind each garment. As the industry embraces new trends, such as AI and robotics, the partnership between cutting and sewing will remain essential in shaping the future of fashion and apparel.