Introduction

Activewear brands face growing consumer demand for eco-conscious products, alongside regulatory requirements that encourage, or in some cases mandate, carbon neutrality. In addition to the regulatory landscape, there is a clear shift in consumer behavior—more and more shoppers are looking for brands that demonstrate environmental responsibility. By 2030, activewear manufacturers in the EU will need to meet stringent carbon neutrality standards, and those who adapt early will have a significant advantage over competitors.

This article will explore three key strategies that can help activewear brands achieve carbon neutrality by 2030, offering practical solutions and real-world applications to guide brands toward a more sustainable future.

The Problem: Carbon Emissions in Activewear Manufacturing

The activewear industry, while catering to an increasingly eco-conscious consumer base, remains one of the highest contributors to carbon emissions within the textile sector. From raw material sourcing to the final product, every step in the activewear manufacturing process adds to its carbon footprint. Here are the key areas of concern:

High-Impact Production Processes

The production of synthetic fibers like polyester and nylon is one of the biggest culprits in terms of carbon emissions. These fibers are derived from petroleum-based products, and their manufacturing requires substantial energy input. The production of polyester alone accounts for roughly 70 million metric tons of CO2 emissions globally each year, which is comparable to the emissions of entire countries like the UK.

In addition, traditional textile dyeing processes, particularly those used for activewear fabrics, are energy-intensive and involve harmful chemicals. One kilogram of fabric dyeing can emit 2.5 kg of CO2, and textile dyeing accounts for about 20% of global water pollution. If left unaddressed, these processes will continue to pose significant environmental challenges.

Material Waste

Activewear production often results in substantial material waste. For instance, approximately 15% of materials are wasted during garment manufacturing, from cutting room floors to defective materials. Even when recycled materials are used, such as PET bottles turned into fabric, the recycling process still requires significant energy input. Additionally, waste during packaging and shipping contributes further to the overall environmental impact.

Many activewear brands continue to rely on virgin polyester and non-biodegradable materials, which only add to the pollution when these items inevitably end up in landfills. When synthetic fabrics are discarded, they can take hundreds of years to break down, releasing microplastics into the environment in the process.

Global Supply Chains and Transportation

The global nature of the activewear industry means that products often travel long distances before reaching consumers. The transportation of raw materials, intermediate products, and finished goods across continents significantly contributes to carbon emissions. According to a report by the International Transport Forum, shipping and air transport combined account for 5-6% of global carbon emissions.

For example, when activewear brands source materials from one country, ship them to a factory in another, and then deliver finished products to multiple international markets, the carbon emissions from logistics can rival or even exceed the emissions from manufacturing itself. With growing demand for products in distant markets, brands must carefully assess the carbon footprint of their entire supply chain.

Regulatory Pressure and Consumer Demands

The push for carbon-neutral production is not only driven by regulatory requirements, like the EU’s 2030 mandate, but also by a shifting market. Consumers are increasingly seeking brands that prioritize environmental responsibility. According to a 2021 study, 66% of global consumers are willing to pay more for sustainable products, and this percentage is even higher among younger generations.

Failure to address carbon emissions could lead to a loss of market share and reputational damage, especially as consumers become more informed about the environmental impact of the products they purchase. Brands that do not start preparing for stricter emissions standards will be at risk of losing relevance in an increasingly eco-conscious market.

The Solution: Three Key Strategies for Going Carbon Neutral

To achieve carbon neutrality by 2030, activewear brands need to implement sustainable practices across their operations. Here are three key strategies that can help reduce emissions and prepare for future regulations:

a. Switch to Sustainable Materials

One of the most effective ways to reduce carbon emissions is by using sustainable materials. Brands can move away from virgin polyester and instead adopt recycled fabrics, organic cotton, or plant-based fibers like bamboo or hemp. Recycled polyester, made from PET bottles, uses significantly less energy to produce than virgin polyester and keeps plastic waste out of landfills.

Switching to natural, biodegradable fibers also reduces long-term environmental impact. For instance, organic cotton requires less water and fewer pesticides than conventional cotton, and hemp is highly sustainable, growing quickly with minimal resources.

b. Optimize Energy and Water Use in Manufacturing

Manufacturers can significantly reduce emissions by integrating renewable energy sources (e.g., solar, wind) into production processes. Additionally, adopting water-saving dyeing technologies like air-dyeing or waterless dyeing can cut down on water use and associated emissions.

Upgrading to energy-efficient machinery and establishing closed-loop systems—where water and energy are recycled within the facility—also reduces the carbon footprint of manufacturing. This approach not only reduces emissions but also cuts operational costs over time.

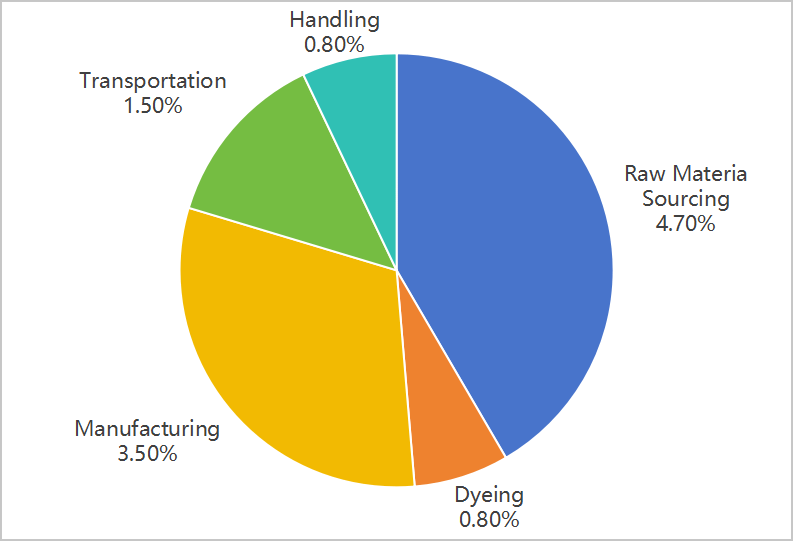

c. Track Emissions and Offset Smartly

Activewear brands can use lifecycle analysis (LCA) tools to measure emissions across all stages of product development, from raw material sourcing to transportation. By tracking their carbon footprint, brands can identify the highest-emitting processes and target them for improvement.

Where emissions cannot be eliminated, smart carbon offsetting becomes essential. Brands can invest in projects such as reforestation, renewable energy, or carbon capture technologies to offset their emissions. Transparency in these efforts—like using blockchain for traceability—builds consumer trust and enhances brand credibility.

| Type of energy | Summation term: carbon savings (billion tons) |

| Wind Energy | 5.3 |

| Mixed | 3.8 |

| Solar | 18.5 |

| Total | 27.6 |

Conclusion: Why Activewear Brands Must Act Now

The need for activewear brands to go carbon neutral by 2030 is not just about meeting regulatory demands—it’s also an opportunity to engage with a growing base of eco-conscious consumers. By adopting sustainable materials, optimizing production processes, and tracking emissions, brands can not only reduce their carbon footprint but also lead the way in an industry that is increasingly focused on environmental impact.

At GOPHERWOOD, we are committed to helping our partners navigate the transition to sustainable manufacturing. With our expertise in eco-friendly materials and carbon-efficient production, we provide activewear brands with the tools they need to reduce emissions and achieve carbon neutrality. Contact us today to learn more about how we can help you make the switch to a more sustainable future.