Introduction

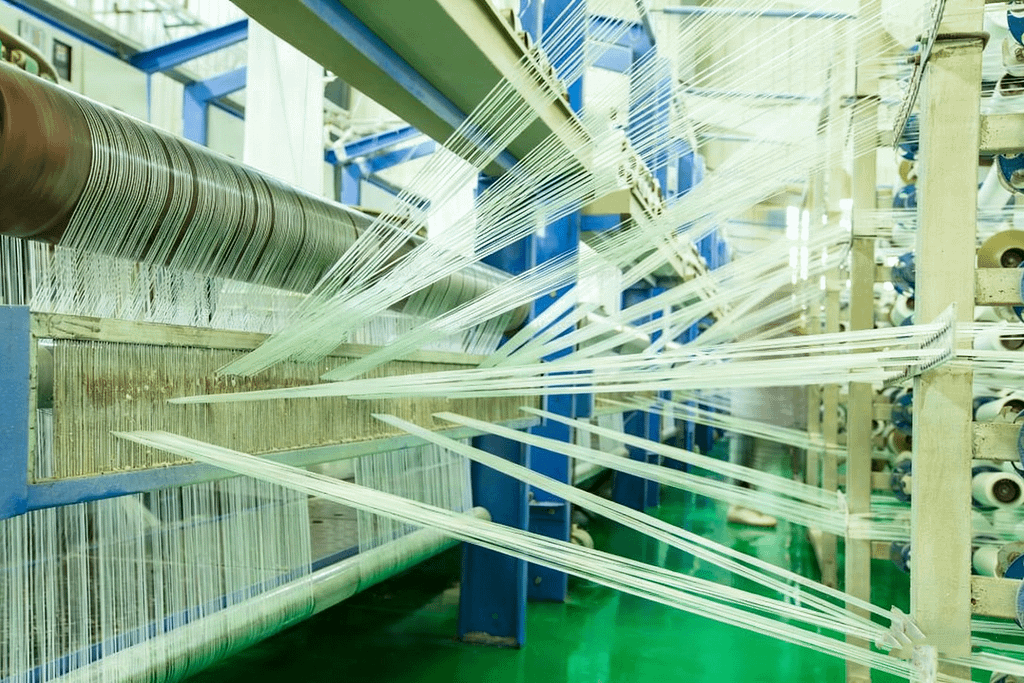

In textiles, every fabric tells a story through its structure and feel. Behind this lies a balance of technical and sensory qualities that shape how a fabric performs and how it is perceived. Among the most important factors are yarn count, fabric weight, and hand feel—often referred to as the “textile trio.”

Understanding these three aspects is essential for anyone involved in fabrics, whether you’re a designer choosing materials, a manufacturer maintaining quality, or a consumer looking for comfort and durability. Yarn count defines the fineness of the thread, fabric weight reflects the density and heaviness of the cloth, and hand feel captures the tactile impression when touched. Together, they provide a complete picture of fabric quality and usability.

Yarn Count

Yarn count is a fundamental measurement in textiles that indicates the thickness or fineness of yarn. In simple terms, it tells us how many units of length are contained in a unit of weight—or vice versa—depending on the system used. A higher yarn count generally means a finer yarn, while a lower count indicates a thicker, coarser yarn. This plays a key role in determining the softness, transparency, and overall appearance of the fabric.

There are several systems for expressing yarn count, including English count (Ne), which measures the number of hanks of yarn in one pound; Metric count (Nm), which measures meters per gram; and Denier or Tex, commonly used in synthetic fibers, where denier represents grams per 9,000 meters of yarn and tex represents grams per 1,000 meters. Designers and manufacturers select yarn counts carefully to match the intended fabric qualities, such as durability for workwear or fineness for luxury fabrics.

Fabric Weight

Fabric weight measures how heavy or dense a fabric is, usually expressed in grams per square meter (GSM) or ounces per square yard (oz/yd²). It gives an objective value that helps compare fabrics beyond just appearance. Lightweight fabrics, such as chiffon or voile, typically fall below 150 GSM and are valued for breathability and drape. Medium-weight fabrics, ranging from 150–300 GSM, include versatile options like cotton shirting and denim. Heavyweight fabrics, over 300 GSM, such as canvas or upholstery textiles, are prized for durability and structure.

The weight of a fabric influences not only its performance but also its comfort and suitability for different uses. For example, a lightweight cotton is ideal for summer wear, while a heavyweight wool provides insulation in colder climates. Fabric weight also affects the drape and silhouette of garments—designers must consider this carefully when choosing materials to achieve the desired style and functionality.

Hand Feel

Hand feel, also known as fabric hand, describes the tactile sensations experienced when touching a fabric. It encompasses qualities such as softness, smoothness, crispness, stiffness, or stretchiness, providing an immediate sense of comfort and quality. While yarn count and fabric weight are measurable, hand feel is more subjective but equally important, as it directly affects how a garment feels against the skin.

Several factors influence hand feel, including fiber type, yarn structure, weave or knit pattern, and any finishing treatments applied to the fabric. For instance, a high-count cotton with a sateen finish can feel silky and smooth, while a coarse wool might feel textured and warm. Hand feel is crucial in the textile and apparel industry because it shapes consumer perception, guides fabric selection for specific applications, and enhances the overall user experience.

Interconnection of the Trio

- Yarn Count Sets the Foundation:

- Fine yarns result in smooth, soft, and often lightweight fabrics, ideal for garments that require drape and delicacy.

- Coarse or low-count yarns create thicker, more textured fabrics that provide strength and durability, suitable for heavy-duty or structured applications.

- The choice of yarn count also affects the fabric’s appearance, opacity, and flexibility, influencing how it reacts during cutting and sewing.

- Fabric Weight Complements Yarn Count:

- Fabric weight determines the density and heft of a textile, directly affecting its drape, thermal properties, and stability.

- Lightweight fabrics enhance fluidity and comfort, while medium- and heavyweight fabrics provide support, insulation, and resilience.

- When paired with appropriate yarn counts, fabric weight ensures the intended aesthetic and functional properties of the finished material.

- Hand Feel Reflects Combined Effects:

- Hand feel synthesizes tactile qualities influenced by yarn structure, fabric weight, and finishing processes.

- It conveys softness, crispness, smoothness, or texture, directly affecting user perception and garment desirability.

- The interaction of yarn count and weight dictates whether a fabric feels delicate, substantial, luxurious, or rugged.

- Professional Implications:

- Designers and textile engineers can strategically combine yarn counts and fabric weights to achieve desired hand feel and performance.

- High-count fine yarn + lightweight fabric → soft, fluid, and luxurious textiles (ideal for blouses, scarves, or lingerie).

- Low-count coarse yarn + heavyweight fabric → sturdy, textured, and structured textiles (used in outerwear, upholstery, or industrial fabrics).

- Awareness of these relationships improves efficiency in production, quality control, and material selection.

Applications in the Textile Industry

Understanding the interplay of yarn count, fabric weight, and hand feel is critical across multiple segments of the textile industry. Designers use this knowledge to select fabrics that align with a garment’s purpose and aesthetic, ensuring that the finished product meets both functional and visual expectations. For example, sportswear often prioritizes lightweight fabrics with fine yarns for breathability and comfort, while outerwear relies on heavier fabrics with coarser yarns for durability and insulation.

In manufacturing, the textile trio guides quality control and production planning. Accurate knowledge of yarn count and fabric weight ensures consistency across batches, while assessing hand feel helps maintain product standards that appeal to end users. In the luxury market, hand feel is particularly emphasized, as it directly influences perceived value and customer satisfaction. Beyond apparel, these principles are applied in upholstery, home textiles, and technical fabrics, where the right balance of strength, weight, and tactile quality determines usability and longevity.

Practical Tips for Fabric Selection

When selecting fabrics, it is important to consider the intended end use, balancing aesthetics, comfort, and performance. Start by identifying the garment type and its functional requirements—whether it needs to be lightweight and breathable for summer wear, or heavier and durable for outerwear. Yarn count should be matched to the desired hand feel: higher-count yarns create softer, finer fabrics, while lower-count yarns result in thicker, more textured materials. Fabric weight, expressed in GSM or oz/yd², provides a reliable guideline for assessing the fabric’s density and suitability for different applications.

Hand feel should be evaluated by handling samples directly, observing both texture and drape. Consider how the fabric behaves when folded, stretched, or moved, as this can influence comfort and garment appearance. Fiber type and finishing processes also play a key role, affecting softness, breathability, stretch, and washability. For manufacturing purposes, practical tests such as sewability, seam stability, shrinkage, and wash performance help ensure consistent quality in bulk production. Whenever possible, request technical data including yarn count, GSM, and laboratory test results for abrasion resistance, pilling, and tensile strength to make informed decisions and achieve the best balance between functionality and tactile appeal.

Conclusion

Yarn count, fabric weight, and hand feel together form the foundation of fabric quality and performance. Each element contributes uniquely—yarn count defines fineness, fabric weight determines density and drape, and hand feel captures the tactile experience. Understanding their interplay allows designers, manufacturers, and consumers to make informed choices that balance aesthetics, comfort, and durability. By considering the textile trio in fabric selection, it becomes possible to achieve garments and textiles that not only look appealing but also perform reliably, ensuring satisfaction from production to end use.

As a B2B cross-border clothing manufacturer, GOPHERWOOD leverages this expertise to provide high-quality fabrics and garments tailored to international markets, helping brands deliver exceptional products with consistent quality and comfort.