Introduction

Polypropylene fabric has become a cornerstone in both industrial and everyday applications thanks to its impressive balance of strength, lightness, and adaptability. Originally developed as a thermoplastic polymer, it has evolved into a widely used textile material known for its resistance to moisture, chemicals, and wear.

From medical supplies and activewear to reusable shopping bags and agricultural covers, polypropylene fabric proves itself time and again in environments where performance matters most. This article explores the origin, properties, variations, and uses of polypropylene fabric—highlighting why it’s a go-to solution in modern material needs.

Origins and Development

Polypropylene was first polymerized in the 1950s by Italian chemist Giulio Natta, who went on to win a Nobel Prize for his work in polymer chemistry. This thermoplastic polymer quickly gained attention for its strength, chemical resistance, and ease of processing, making it suitable for a variety of commercial uses.

Its transition into textiles began with the development of fiber extrusion techniques that allowed polypropylene to be spun into threads, woven into fabrics, or processed into nonwoven materials. Over the decades, advances in manufacturing have made polypropylene one of the most widely produced synthetic fibers in the world—used in everything from disposable medical garments to long-lasting outdoor equipment.

What Is Polypropylene Fabric?

Polypropylene fabric is a synthetic textile made from polypropylene, a type of thermoplastic polymer belonging to the polyolefin family. It is created through a process where polypropylene pellets are melted and extruded into fibers, which are then processed into woven or nonwoven fabric forms.

What makes polypropylene fabric distinct is its chemical structure: it repels water, resists stains, and doesn’t absorb moisture—giving it a naturally hydrophobic quality. It is also lightweight, strong, and has a low density, making it ideal for applications where minimal weight and high durability are important. Available in both rigid and flexible forms, polypropylene fabric can be engineered to suit everything from single-use items to heavy-duty industrial needs.

Key Properties and Benefits

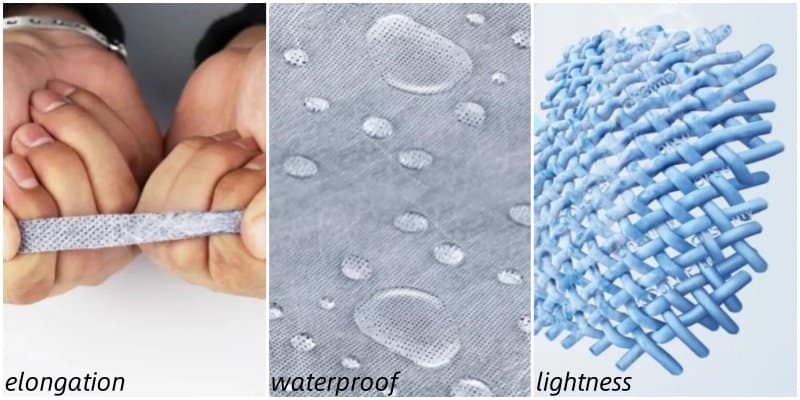

Polypropylene fabric is valued for its unique combination of performance features, making it suitable for a wide range of demanding environments. Here are its most notable properties:

- Lightweight: Polypropylene is one of the lightest synthetic fibers available, which makes it ideal for applications where minimizing bulk and weight is important—like reusable bags, masks, or activewear.

- Durable: Despite being lightweight, it is tough and abrasion-resistant, holding up well under repeated use and stress without breaking down easily.

- Water-Resistant: Naturally hydrophobic, polypropylene does not absorb water. This property also helps it dry quickly and resist mold or mildew growth.

- Stain-Resistant: The fabric repels most oils and chemicals, making it easy to clean and maintain.

- Chemical and UV Resistant: Polypropylene holds up well against many chemicals and, when treated, can resist degradation from sunlight, which is especially useful in outdoor applications.

- Breathable (Nonwoven Types): Nonwoven versions like spunbond and meltblown polypropylene allow air to pass through while still offering protection—ideal for items like surgical masks and filters.

- Cost-Effective: Compared to many other performance textiles, polypropylene is inexpensive to produce, making it accessible for both disposable and long-term use.

Types of Polypropylene Fabrics

Polypropylene fabrics come in several forms, each tailored to specific applications. Here are the most common types:

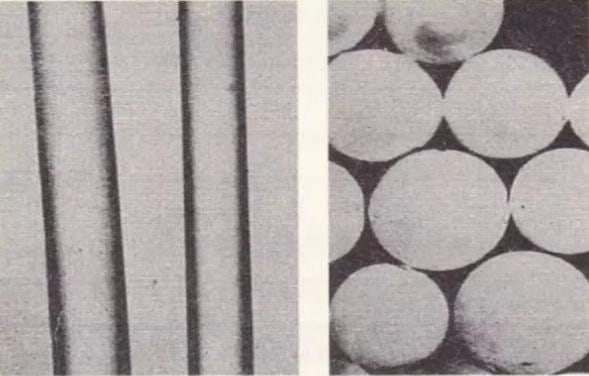

- Woven Polypropylene

Made by weaving polypropylene threads in a crisscross pattern, this fabric is strong and tear-resistant. It’s commonly used in packaging materials such as rice or sandbags, geotextiles, and tarpaulins.

- Nonwoven Polypropylene

Created by bonding fibers together rather than weaving them, this version is used widely in disposable applications like surgical masks, medical gowns, and hygiene products. It’s lightweight, breathable, and cost-effective.

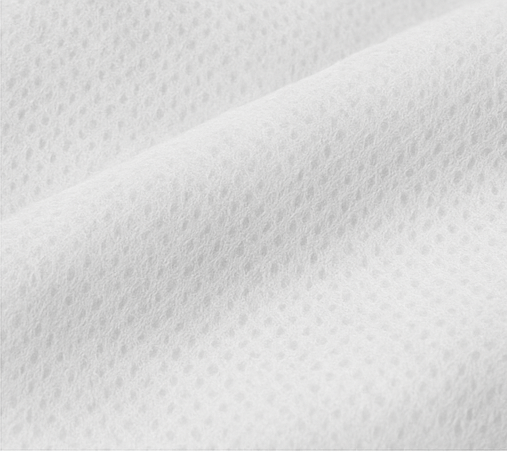

- Spunbond Polypropylene

A subtype of nonwoven fabric, spunbond polypropylene is made by spinning fibers directly from the polymer and bonding them with heat. It is durable yet breathable, making it ideal for filters, protective clothing, and furniture linings.

- Meltblown Polypropylene

Finer than spunbond, meltblown fabric is used where higher filtration efficiency is needed, such as in the middle layer of N95 masks or industrial filters.

- Laminated Polypropylene

This type features a polypropylene film bonded to a woven or nonwoven fabric. It offers extra protection against moisture and contaminants, making it suitable for items like reusable shopping bags or protective covers.

Common Applications

Polypropylene fabric is used across a wide range of industries due to its affordability, functionality, and versatility. Here are some of its most prominent applications:

- Medical Field

Nonwoven polypropylene is essential in disposable medical products like surgical masks, gowns, shoe covers, and hospital bedding. Its breathability and resistance to fluids make it ideal for sterile environments. - Agriculture

Woven polypropylene is used for crop covers, weed barriers, and sacks for storing grains and fertilizers. It withstands moisture and exposure to sunlight when UV-treated. - Fashion and Apparel

While not typically used as a primary fabric in fashion, polypropylene is often found in thermal underwear, sportswear linings, and accessories that benefit from its moisture-wicking and insulating properties. - Industrial Use

In industries, polypropylene fabrics are used in construction materials, insulation layers, and geotextiles for soil stabilization and erosion control. - Home and Consumer Goods

Items like reusable shopping bags, upholstery backing, furniture linings, and storage containers often incorporate polypropylene for its durability and water resistance.

Production Process

Polypropylene fabric is manufactured through a series of engineered steps that transform raw polymer pellets into durable textile forms. Here’s an overview of the process:

Production Overview:

Polypropylene production begins with the polymerization of propylene gas into solid plastic pellets. These pellets are melted and extruded into fibers, which are then processed into either woven or nonwoven fabrics depending on the desired end use. Modern techniques like spunbond and meltblown allow for mass production of nonwoven fabrics used in medical and industrial sectors.

Polypropylene Fabric Production Process

| Step | Description |

|---|---|

| 1. Polymerization | Propylene gas is polymerized to form polypropylene resin (plastic pellets). |

| 2. Melting and Extrusion | Pellets are melted and extruded into continuous fibers or filaments. |

| 3. Spinning | The extruded fibers are cooled and stretched to improve strength. |

| 4. Web Formation | For nonwoven fabrics, fibers are laid into a web using spunbond or meltblown techniques. |

| 5. Bonding | Fibers are thermally bonded (heat and pressure) to form a stable fabric sheet. |

| 6. Weaving (if applicable) | For woven polypropylene, fibers are woven into a crisscross pattern. |

| 7. Finishing | UV treatment, lamination, or surface enhancements are applied based on the final application. |

| 8. Cutting and Packaging | Fabric is cut to size, rolled, and packaged for distribution. |

Care and Maintenance

Polypropylene fabric is low-maintenance, which adds to its appeal for both disposable and reusable products. Proper care ensures longer-lasting performance, especially for reusable items like bags, linings, or outdoor covers.

- Washing: Most polypropylene fabrics can be hand-washed or machine-washed in cold to warm water using mild detergent. Avoid using hot water, as it may affect the structure due to the fabric’s low melting point.

- Drying: Air drying is recommended. If using a dryer, choose a low or no-heat setting to prevent shrinkage or melting.

- Ironing: Generally not required and should be avoided unless specified. Direct heat may damage the fibers.

- Storage: Store in a cool, dry place away from direct sunlight to avoid UV degradation, especially if the fabric is untreated.

- Stain Removal: The fabric’s stain-resistant nature makes it easy to wipe clean. For tougher stains, gentle scrubbing with soap and water usually suffices.

By following these simple steps, polypropylene products can retain their form, functionality, and cleanliness over time.

Conclusion

Polypropylene fabric stands out as a practical, high-performance textile that meets the demands of diverse industries—from healthcare and agriculture to fashion and consumer goods. Its lightweight nature, resistance to moisture and chemicals, and cost-efficiency make it a reliable choice for both disposable and long-term use.

While it has limitations, especially regarding heat sensitivity and UV exposure, ongoing innovations are steadily improving its performance and sustainability. As material science advances, polypropylene remains a fabric that not only serves current needs but also adapts to the challenges of the future.