Introduction

Pockets are more than just functional additions to clothing—they’re integral design elements that influence the form, function, and fashion of a garment. In modern apparel design, pocket structures are carefully considered not only for their practicality but also for how they contribute to the overall aesthetic and brand identity.

Each type is explained with its design purpose, functional benefit, common applications, and useful tips for both design teams and manufacturing partners. Consider this a practical guide to help you make informed decisions in your apparel development workflow.

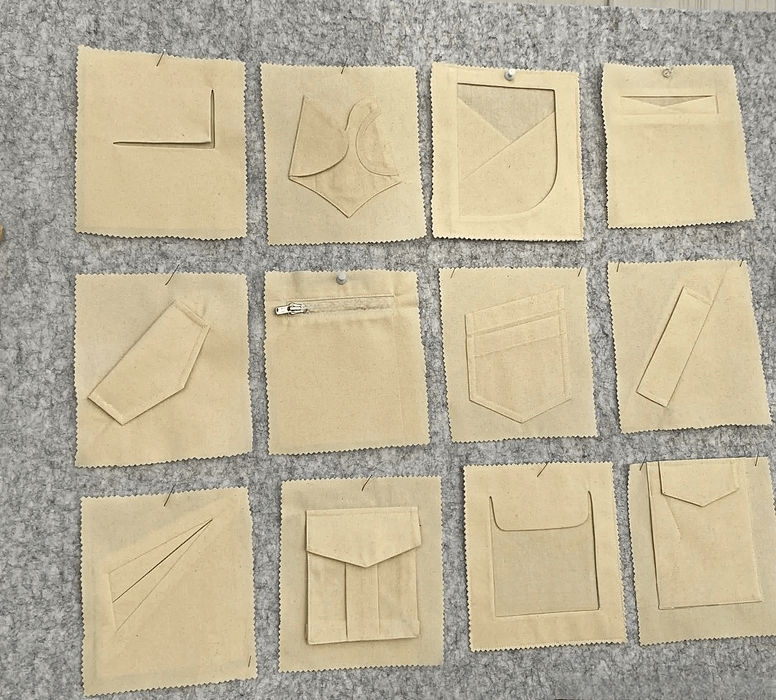

Nine common types of pocket structures

Flat Patch Pocket

The flat patch pocket is one of the simplest and most widely used pocket structures. It is made by stitching a separate piece of fabric directly onto the garment’s surface, forming a visible and functional compartment.

This pocket type is commonly seen on shirts, casual jackets, kidswear, and work uniforms. Its clean and straightforward design allows for easy access and adds minimal bulk. Designers often use it as a stylistic element by varying the shape, fabric, or embellishment.

From a manufacturing standpoint, flat patch pockets are cost-effective and easy to sew, making them ideal for mass production. Reinforcing the corners with bar tacks or double stitching ensures durability, especially in garments subject to frequent wear.

Use Case Highlights:

- Design Focus: Functional and decorative

- Applications: Shirts, jackets, uniforms

- Production Note: Simple to construct, low production cost

- Customization Tip: Add embroidery, contrast stitching, or labels for branding

Side Seam Pocket

The side seam pocket is a hidden, built-in pocket located along the garment’s side seams. It’s designed to blend seamlessly with the silhouette, offering storage without interrupting the outer design.

This pocket is widely used in dresses, skirts, trousers, and coats where a clean appearance is essential. It allows for practical hand access while maintaining a streamlined look. Since it’s integrated into the side seams, the pocket remains discreet and functional.

In production, precision is important to ensure the pocket aligns properly and doesn’t distort the garment shape. The choice of lining material also matters, especially when the pocket is added to lightweight or drapey fabrics.

Use Case Highlights:

- Design Focus: Invisible functionality

- Applications: Dresses, skirts, pants, outerwear

- Production Note: Requires precise seam alignment

- Customization Tip: Add inner security features like zippers or reinforced stitching for added value

3D Patch Pocket

The 3D patch pocket, also known as a pleated patch pocket, adds volume and capacity by incorporating pleats or tucks into the pocket structure. Unlike flat patch pockets, these are designed to expand, making them ideal for carrying bulkier items.

Commonly seen on utility garments, cargo pants, military-style jackets, and outdoor wear, this pocket emphasizes functionality and rugged design. Its dimensional shape offers a distinct visual element while serving practical storage needs.

From a production perspective, this pocket requires more fabric and stitching, including pleat formation and secure top edges. Flaps and button closures are often added for security, which can increase labor time but also enhance product value.

Use Case Highlights:

- Design Focus: Utility and added storage

- Applications: Cargo pants, workwear, field jackets

- Production Note: Involves extra construction steps and fabric usage

- Customization Tip: Use contrast stitching or branded hardware to boost the design impact

Accordion Pocket

The accordion pocket features expandable side panels, often pleated like an accordion, allowing the pocket to expand and contract based on what is stored inside. This clever structure maximizes volume without appearing bulky when not in use.

It is often used in utilitarian or performance garments such as backpacks, outerwear, cargo shorts, and functional streetwear. The expandable design ensures flexibility, making it suitable for active or travel-ready pieces.

From a construction standpoint, accordion pockets require careful pleat placement and edge finishing. They may also be secured with flaps, snaps, or Velcro, adding to both functionality and complexity.

Use Case Highlights:

- Design Focus: Flexibility and storage expansion

- Applications: Outerwear, bags, utility pants

- Production Note: More intricate construction with pleating and closure elements

- Customization Tip: Use contrasting fabric or topstitching to highlight the expandable detail

Slanted Pocket

The slanted pocket features an angled opening, usually set at a diagonal from the side seam or front panel. This design offers ergonomic access, especially on trousers and coats, where ease of hand entry is a priority.

Slanted pockets are popular in casual pants, suit trousers, blazers, and outerwear. The angled cut gives garments a refined look and complements the body’s natural movements. It’s a practical style often paired with bar tacks or reinforced stitching at stress points.

In manufacturing, precision is key to maintain symmetry and alignment across both sides of the garment. Lining and reinforcement are also important to prevent sagging or tearing with frequent use.

Use Case Highlights:

- Design Focus: Ergonomic and elegant access

- Applications: Suit pants, casual trousers, blazers, coats

- Production Note: Requires accurate patterning and reinforcement at entry points

- Customization Tip: Add piping or contrast edging to emphasize the slanted line

Cut-In Pocket

The cut-in pocket is created by cutting directly into the garment’s main fabric to form an opening, often without adding extra surface layers. This structure is integrated seamlessly into the garment’s body and usually reinforced with pocket bags and internal facings.

It’s frequently seen in tailored garments like trousers, vests, and formal skirts. The clean, flush appearance maintains the garment’s streamlined silhouette, making it ideal for minimalist or elegant designs.

From a manufacturing view, cut-in pockets require precise cutting, interfacing, and clean finishing. The pocket opening must retain its shape over time, which demands accurate pressing and secure stitching—especially in woven fabrics prone to fraying.

Use Case Highlights:

- Design Focus: Minimalist integration

- Applications: Dress pants, formal skirts, tailored vests

- Production Note: Precision cutting and reinforcement are essential

- Customization Tip: Use contrasting lining or decorative stitching on the interior for subtle luxury

Hidden Pocket

The hidden pocket is designed to be completely invisible from the garment’s exterior. It is usually sewn into linings, waistbands, or behind other pocket structures to store valuables discreetly. With no visible seams or outlines, it offers maximum security and minimal visual disruption.

Commonly used in travel wear, sportswear, outerwear, and safety garments, hidden pockets add utility without affecting the outer design. They are particularly valued for storing money, ID cards, or keys during movement or travel.

In production, hidden pockets require extra steps and planning during construction, especially when inserted between fabric layers or linings. The placement must ensure comfort and accessibility without compromising the fit or silhouette.

Use Case Highlights:

- Design Focus: Discreet functionality and security

- Applications: Jackets, hoodies, travel gear, sportswear

- Production Note: Placement and layering must be carefully managed

- Customization Tip: Use zippers or invisible closures for added safety and value

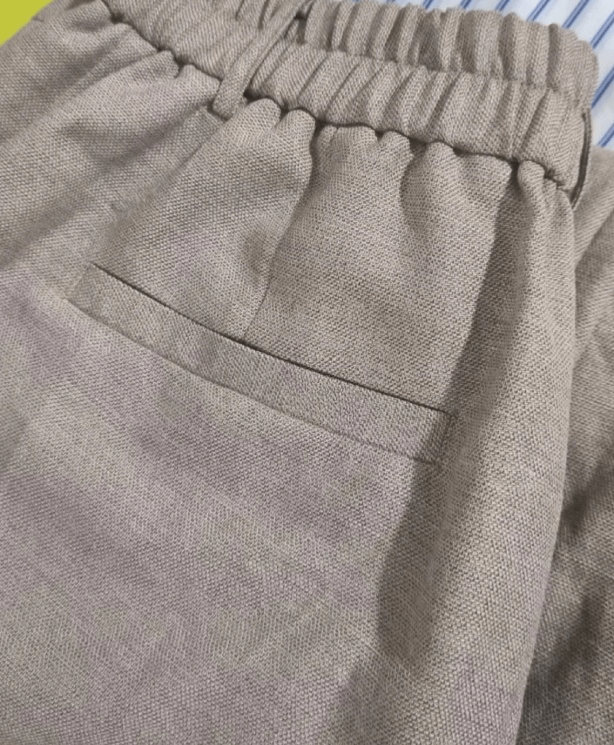

Double-Welt Pocket

The double-welt pocket features two narrow fabric “lips” or welts that border the pocket opening. This design creates a sleek, structured look with a professional finish. Often sewn into the garment surface with an internal pocket bag, it combines elegance with subtle functionality.

You’ll find double-welt pockets in formal garments like suit trousers, blazers, waistcoats, and uniform jackets. They add polish to a design while maintaining a minimal profile, and are frequently used for aesthetic symmetry even when non-functional.

From a production perspective, constructing this pocket demands accuracy in cutting and pressing. The symmetry of the welts and alignment of the opening are crucial, as any misstep will be visually obvious. It’s a more time-intensive process but highly valued in tailored apparel.

Use Case Highlights:

- Design Focus: Clean and formal detailing

- Applications: Suits, blazers, vests, uniforms

- Production Note: Requires precise alignment and clean pressing

- Customization Tip: Add button loops or flaps for decorative and functional enhancements

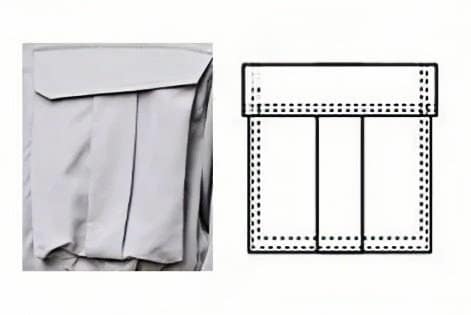

Envelope Chest Pocket

The envelope chest pocket is a flap-style pocket often shaped like an envelope, typically placed on the chest area of shirts, jackets, or coats. Its defining feature is the fold-over flap, which may be secured with buttons, snaps, or Velcro to protect the contents and enhance the design.

This pocket combines decorative appeal with functionality. It’s commonly found in military, safari, and workwear-inspired pieces, as well as casual shirts and denim jackets. The angled or pointed flap adds visual structure and interest.

From a manufacturing perspective, the envelope pocket involves multiple construction steps: the base patch pocket, the flap piece, and any fastening elements. Symmetry and stitching precision are key, especially when pockets are placed in pairs.

Use Case Highlights:

- Design Focus: Structured style with secure closure

- Applications: Casual shirts, denim jackets, outerwear

- Production Note: More steps required; ideal for feature detailing

- Customization Tip: Use branded buttons, shaped flaps, or topstitching to enhance uniqueness

Conclusion

Understanding the structure and function of different pocket styles is essential for both fashion designers and apparel manufacturers. Each pocket type—whether decorative, functional, or both—adds distinct value to a garment in terms of aesthetics, usability, and brand identity.

For apparel businesses, incorporating the right pocket structure can enhance a product’s appeal in diverse markets. Whether you’re designing utility-focused outerwear or sleek formalwear, selecting and executing pocket designs thoughtfully can significantly impact production efficiency and consumer satisfaction.

At GOPHERWOOD, we specialize in apparel manufacturing with a focus on quality, customization, and innovative garment construction. From pocket detailing to full-scale production, we support fashion brands and designers worldwide in bringing their visions to life.

Partner with GOPHERWOOD to elevate your collection with craftsmanship you can trust and design expertise tailored to global markets.